Fishbone Diagrams for Problem Solving

Anne uses fishbone diagrams to identify problems and their causes in quality improvement plans. This involves brainstorming sessions with stakeholders to determine where there is room for improvement. The fishbone diagram helps to identify root problems, rather than just symptoms. This method is effective for collaborative exercises and can help to identify alternative causes that provide innovation to fault analysis.

Value Stream Mapping for Material Flow

Companies must continuously improve to stay competitive.

That's why Anne uses value stream mapping to reduce waste,

following the lean methodology. The waste includes unnecessary

printing, overproduction, movement of products, and extra

processing. Value stream mapping helps create a plan to use

resources efficiently so that materials and time are not

wasted. It is a powerful tool for planning and optimizing

results.

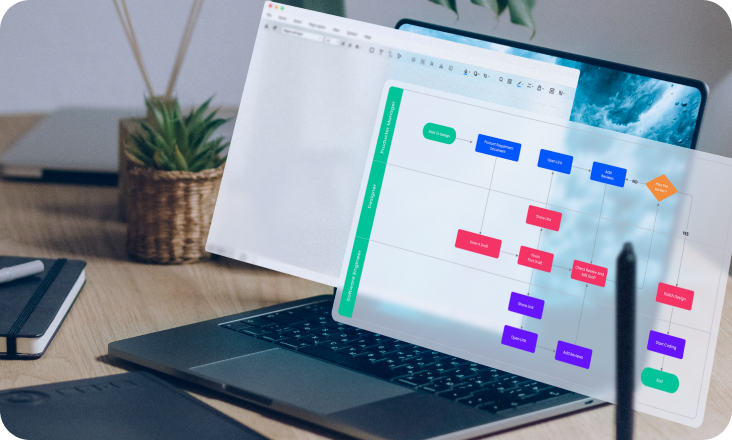

Scheduling Using Gantt Chart

Gantt charts are a tool to assign responsibility for tasks to

team members and help to audit their performance. The function

allows the production staff to plan, control, and optimize

their production plan while taking into account resources and

workforce. Anne found that using Gantt charts helps her team

use resources efficiently, minimize work in progress, and

optimize production order throughput times.