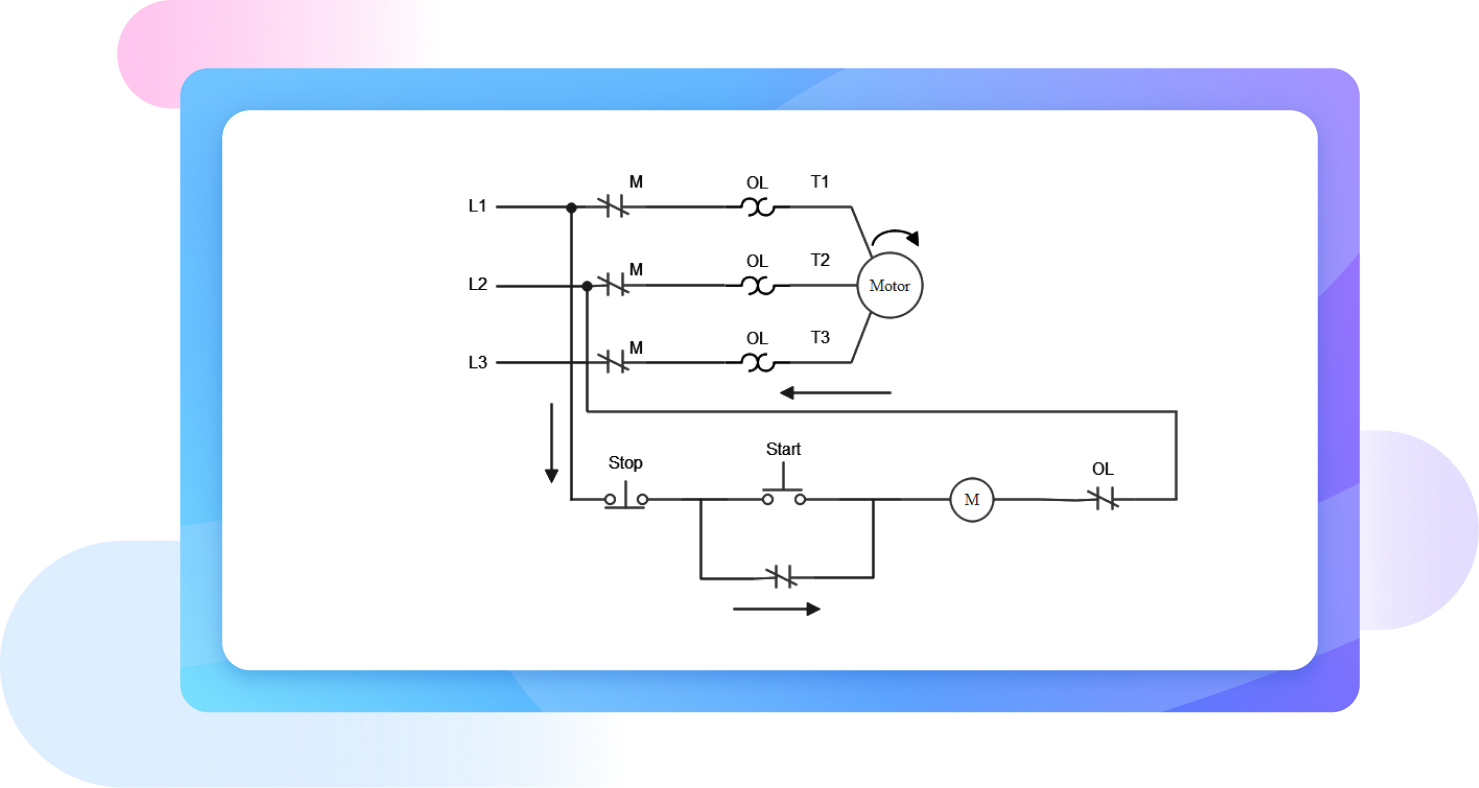

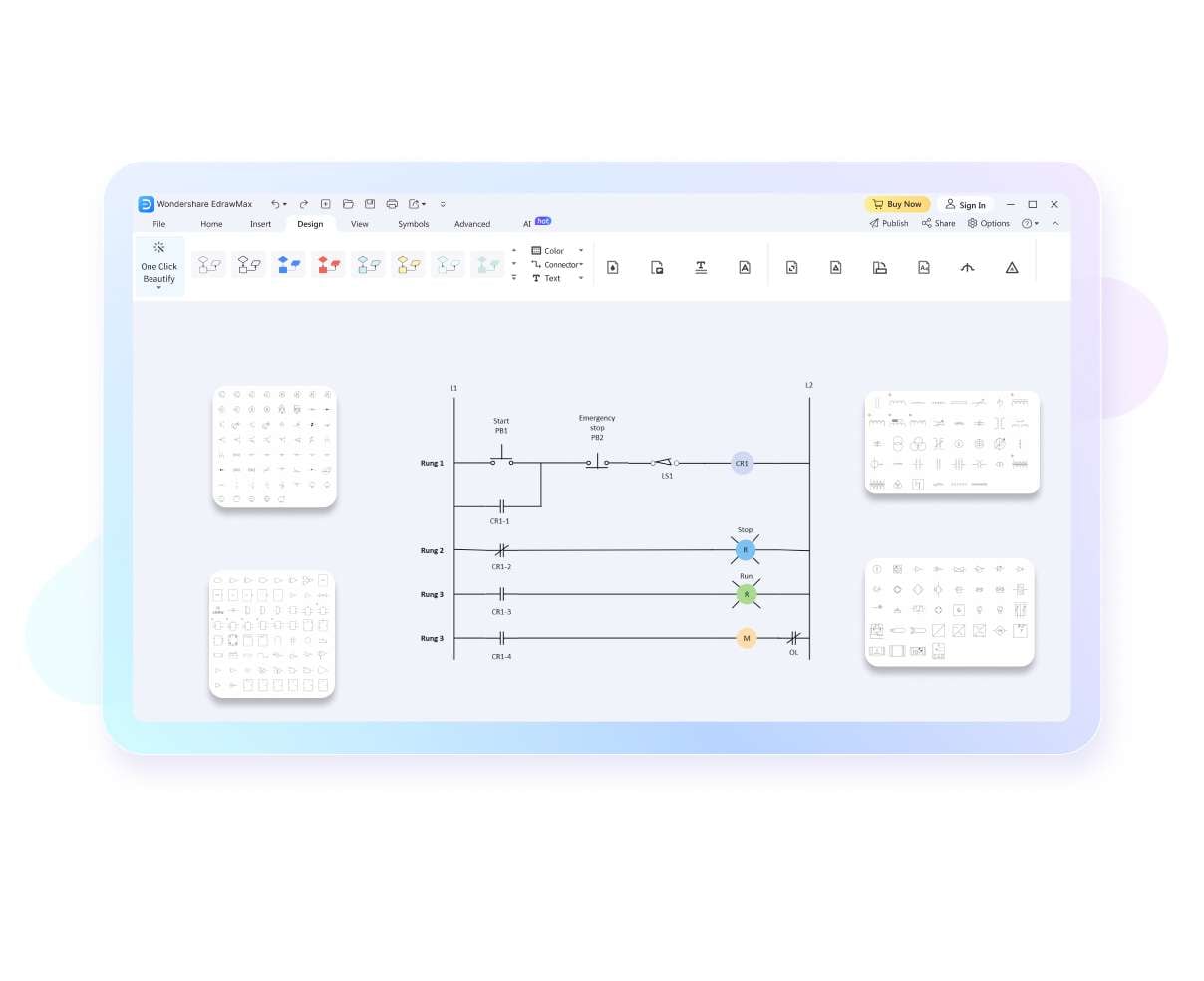

Free ladder diagram maker

Experience excellence with EdrawMax: Your ultimate alternative to CAD and Visio. Explore a vast collection of templates and symbols designed for making ladder diagrams with ease and precision.

Best alternative for CAD software and Visio

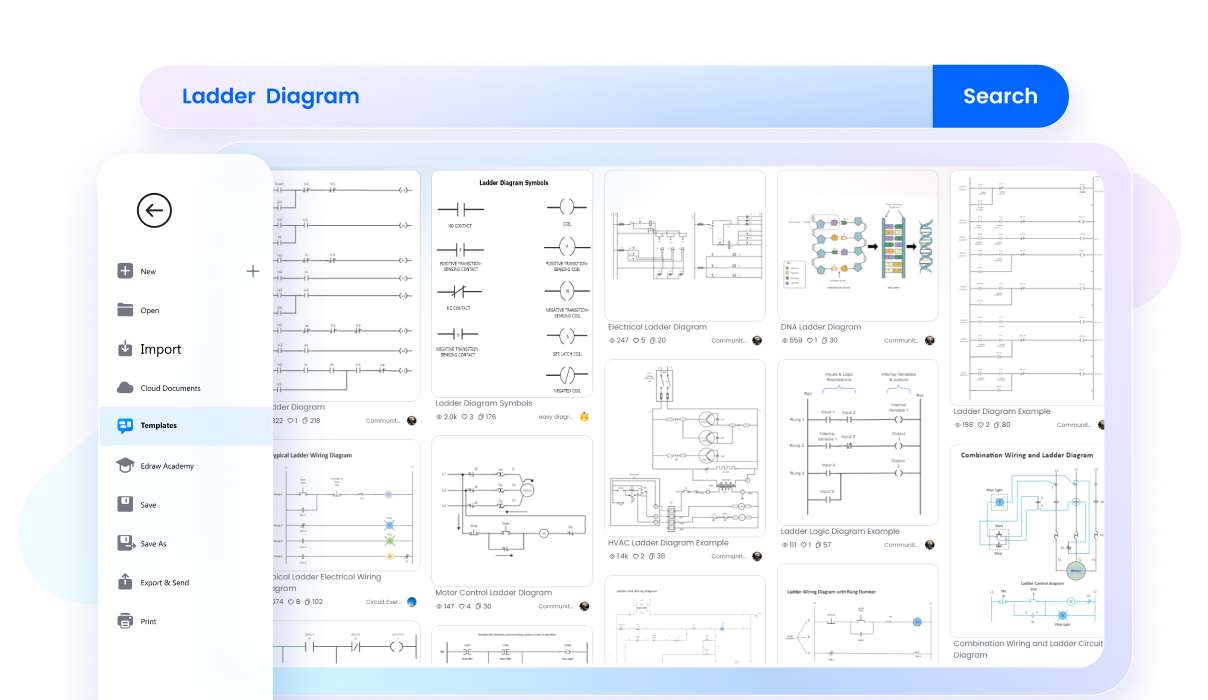

15,000+ templates for all diagram types

Dive into a world of creativity with over 15,000 templates for every diagram type. EdrawMax turns your ideas into stunning visuals, effortlessly.

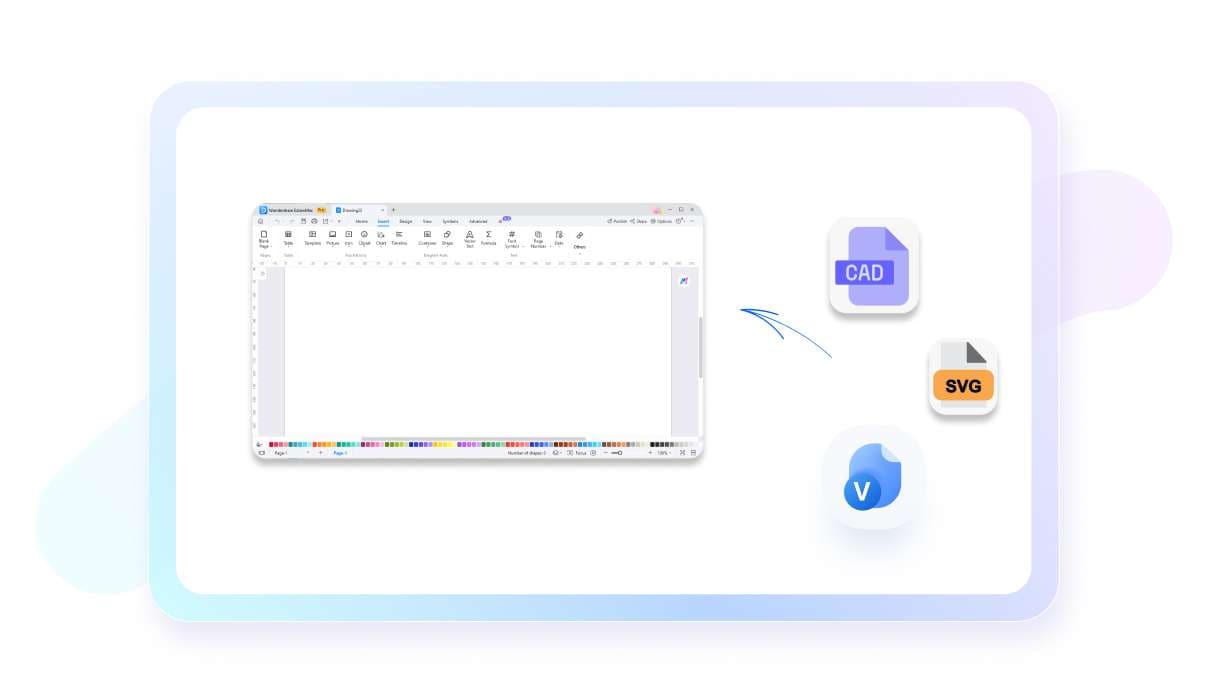

Import CAD, Visio, SVG files at ease

Import from CAD, Visio, SVG with unparalleled ease. EdrawMax bridges your work across platforms, enhancing your design flow.

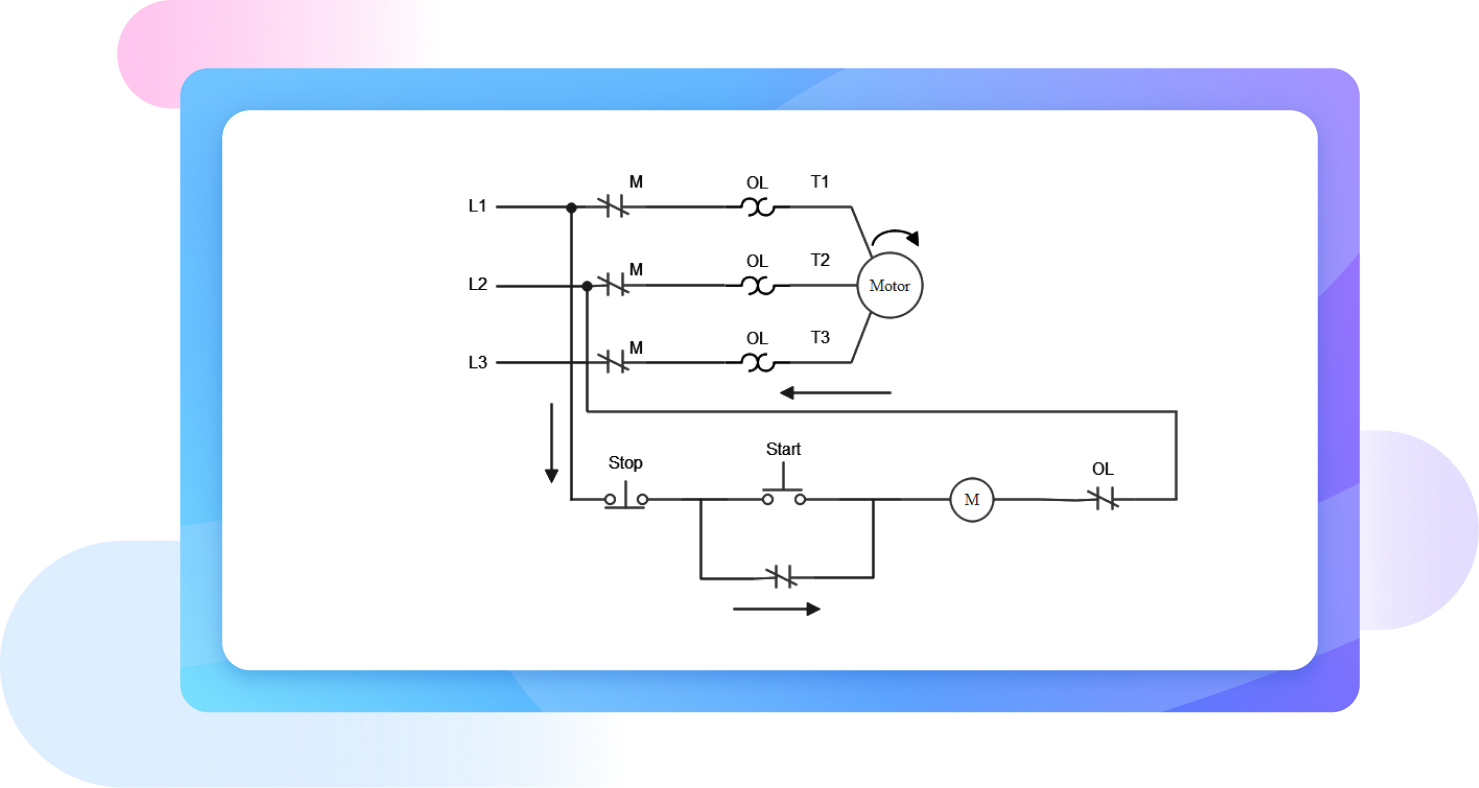

Unrivaled Symbol Library

Access a treasure trove of 26,000 symbols. EdrawMax enriches your diagrams with endless possibilities, making each creation unique.

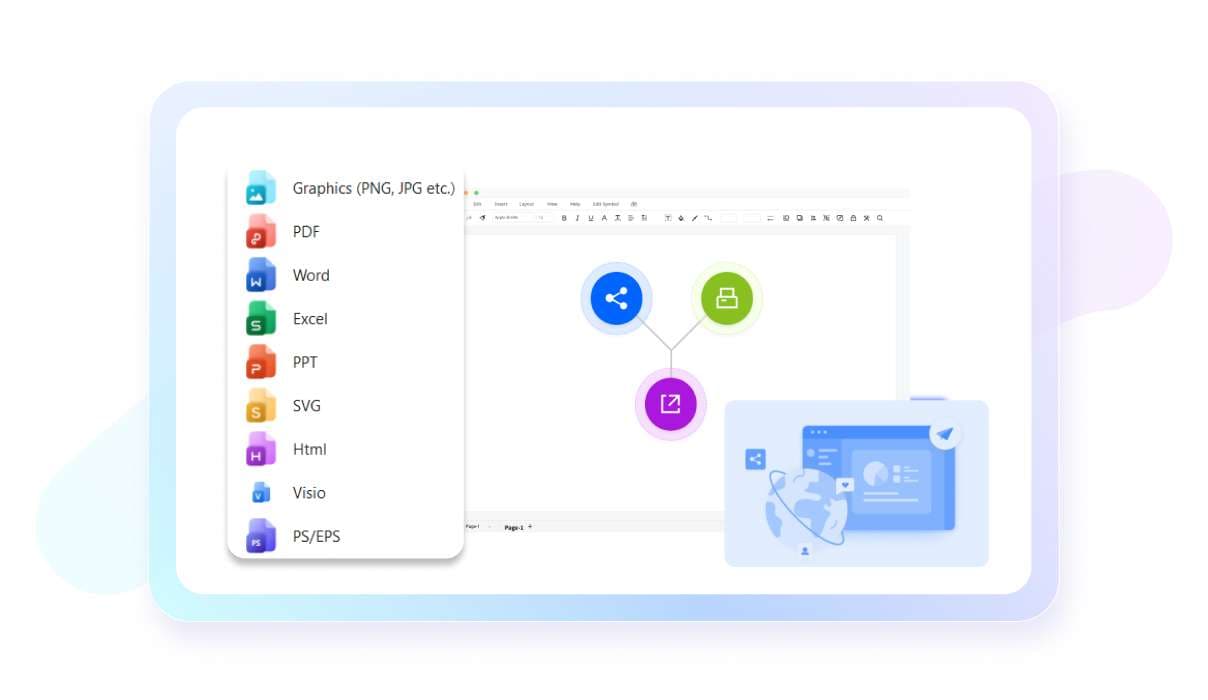

Export files in SVG, Visio, and other formats

Transform and share your diagrams in SVG, Visio, and more. EdrawMax ensures your work is compatible and presentable, wherever it goes.

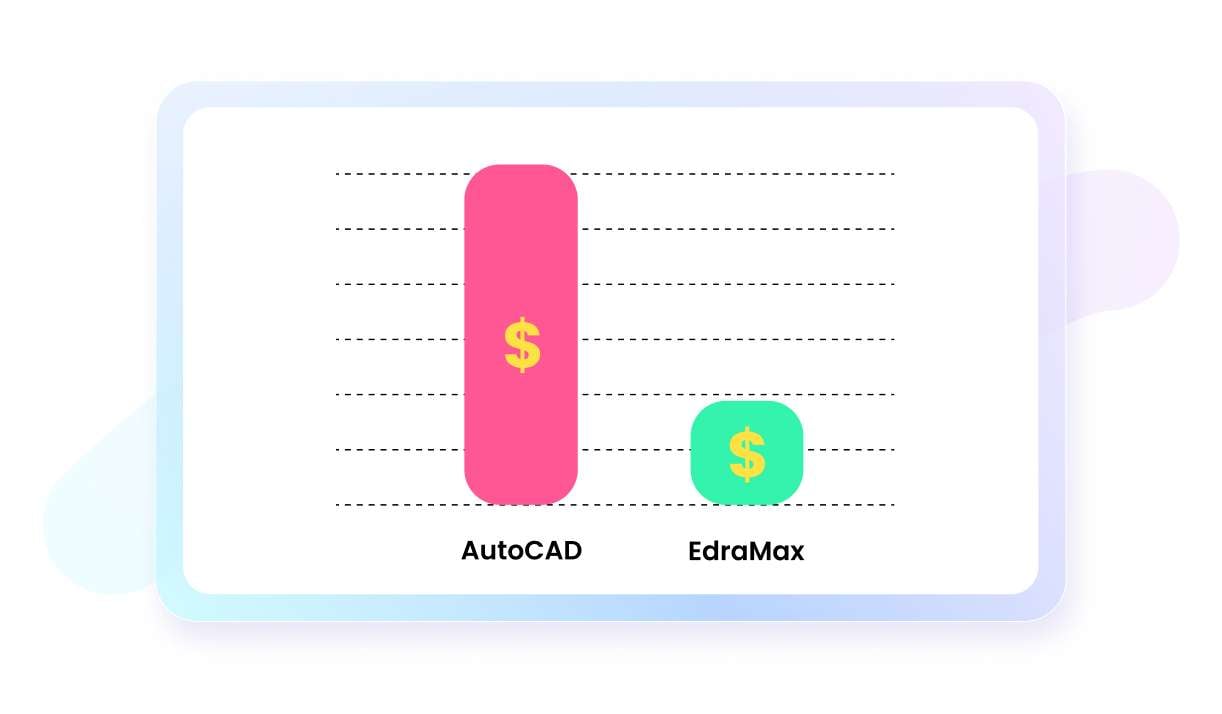

Excellent experience, lower price

Experience premium diagramming at an more affordable price compared to CAD software and Visio. Quality meets affordability, redefining your design journey.

Work without boundaries

EdrawMax empowers you to design anytime, anywhere. Embrace the freedom of remote accessibility, and keep your projects moving forward.

Ladder diagram maker for everyone

Electrical Engineers

Design and troubleshoot electrical control circuits in various industrial settings, ensuring efficient management of complex electrical systems.

Enthusiasts and Hobbyists

Plan and implement home automation projects and other small-scale DIY initiatives, translating complex control logic into manageable plans.

PLC Programmers

Create and modify control logic in Programmable Logic Controllers, which are pivotal in industrial automation.

Automation Professionals

Design and understand the control logic behind the operation of machines and conveyor systems in manufacturing and other automated industries.

Students and Educators

Learn and teach the principles of circuit design and control logic, especially in courses related to electrical engineering and automation.

Maintenance Technicians

Diagnose and fix faults in electrical control systems, particularly in industrial machinery and equipment.

Why teams choose EdrawMax?

Seamless Teamwork

EdrawMax facilitates real-time collaboration, allowing team members to work together on diagrams and share feedback instantly, fostering teamwork, and accelerating project progress.

Enhanced Efficiency

With its intuitive interface, pre-made templates, and extensive symbol libraries, EdrawMax enables teams to create professional-quality diagrams quickly, saving time, reducing effort, and increasing productivity.

All in One

EdrawMax allows for making 210+ types of diagrams including flowcharts, mind mapps, Gantt charts, timelines and more, streamlining workflows and eliminating the need for multiple software, enhancing convenience.

Improved Communication

Use visually compelling diagrams to convey complex ideas, facilitating clear and concise communication within teams and with stakeholders, boosting understanding and decision-making processes.

Types of ladder diagrams

Six steps to make a ladder diagram

What our users say

Ladder diagram templates from EdrawMax

Explore more diagrams

FAQs about ladder diagram makers

Simple, smart, stunning diagrams for every idea.

Wondershare

EdrawMax

An all-in-one platform for 210+ diagrams.

・ Easy-to-use, intuitive Visio Alternative (AI & Web)

(AI & Web)

・ 20,000+ free templates & 26,000+ symbols

・ 40+ AI diagram generators and tools

・ Integration with Nano Banana Pro