- All templates

- Wiring diagram templates

- 7.3 Powerstroke alternator wiring diagram

About this template

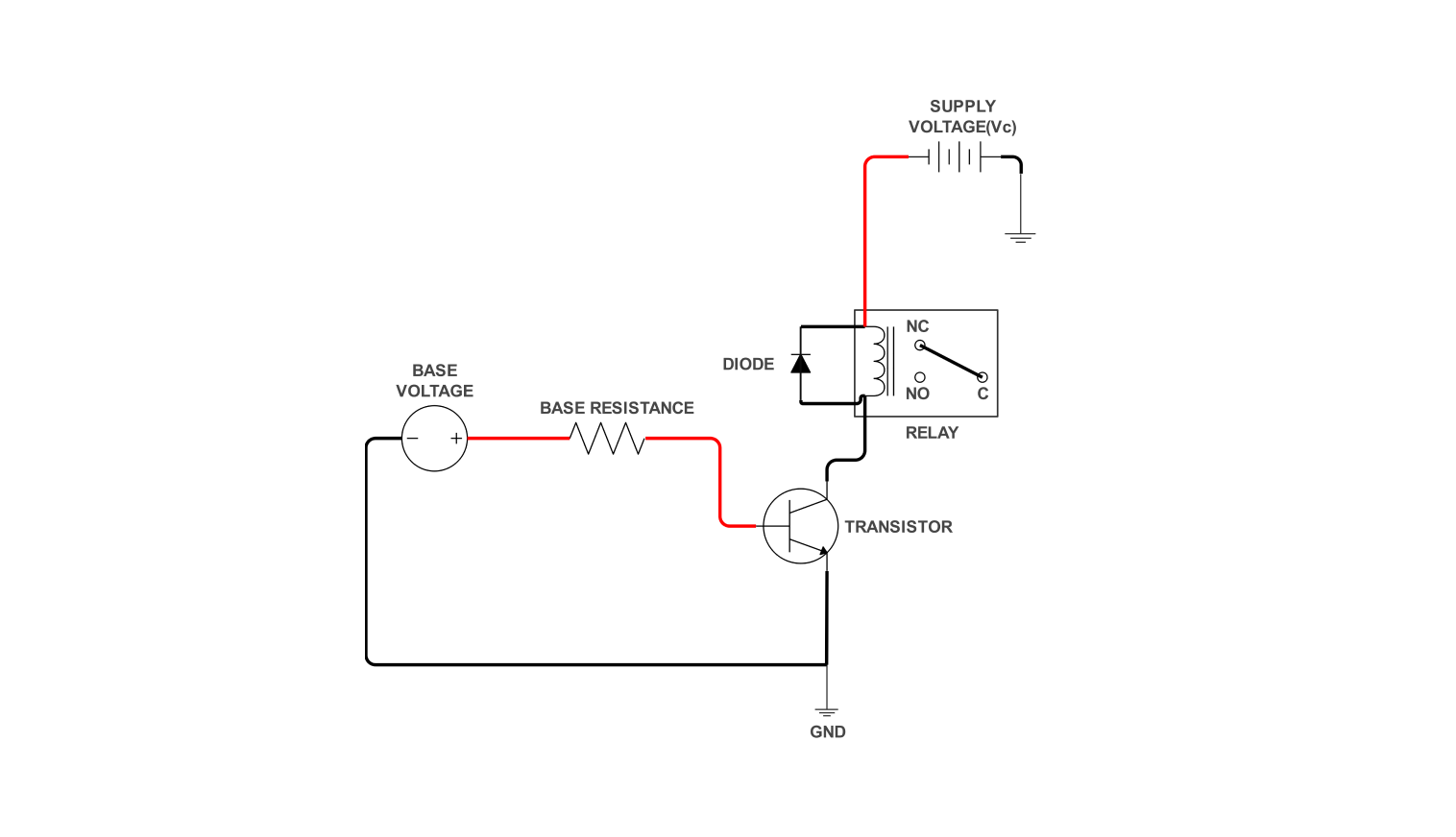

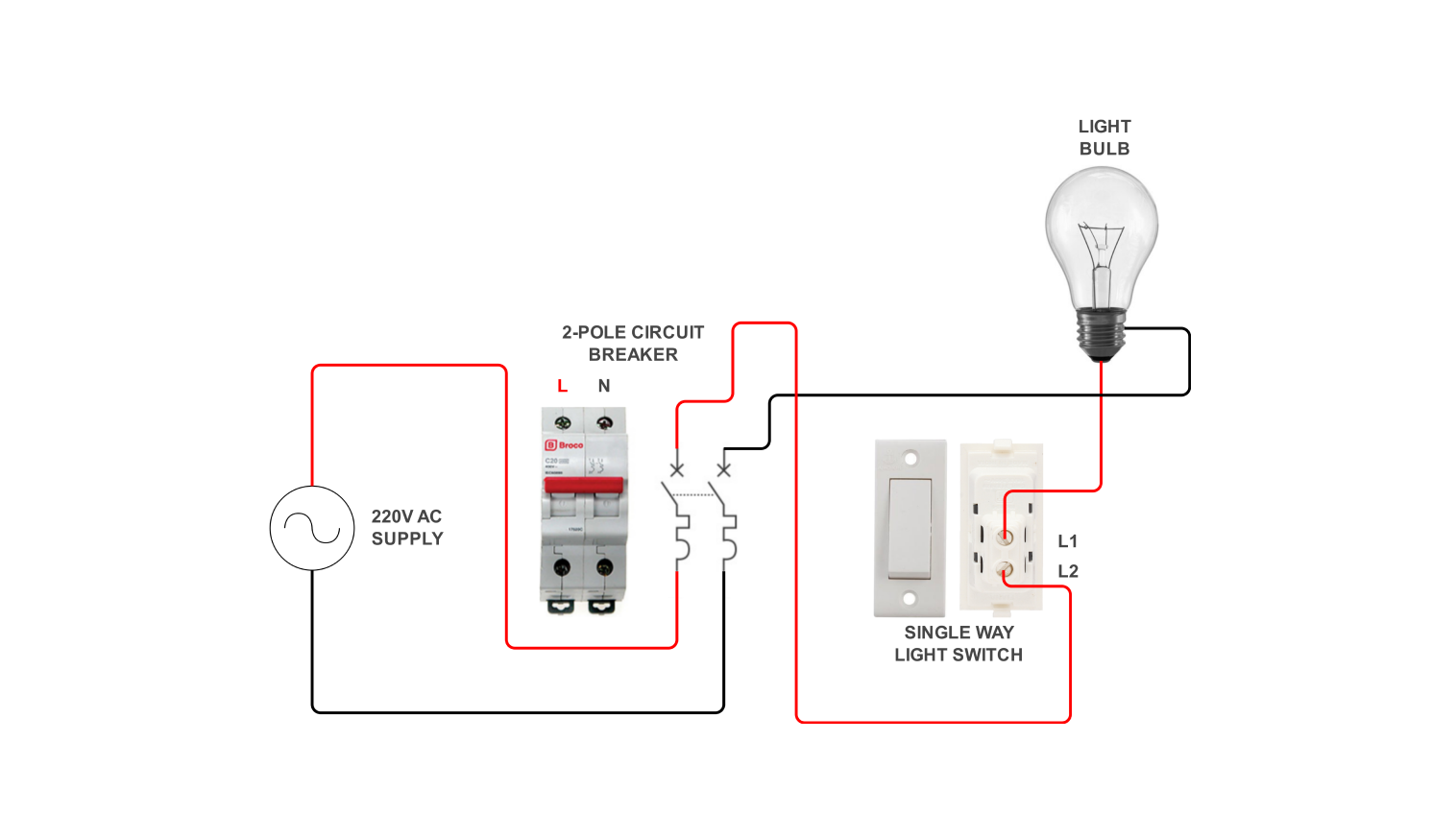

Creating a comprehensive wiring diagram for a 7.3 powerstroke alternator involves detailing the connections among key components crucial for efficient power distribution and reliable operation within the vehicle's electrical system.

One of them is the battery which is the primary energy source needed to start the engine and the electricity storage while the engine is on. The starter relay functions similarly to a high current switch; on the lighting of the spark plug, it opens another circuit to switch on the starter motor to turn the engine using the energy taken from the battery.

Mechanical energy developed by the engine is used for charging the battery and for providing electrical power to all the circuits in the car by the alternator. The information may be transmitted on a regular cluster which is the panel to enable the driver to see figures such as RPMs, speed, fuel, and coolant temperatures.

A charge indicator informs the driver about the charge status of the battery to observe appropriate charges. Fusible links and fuses are incorporated in the circuit so that protection against overload and Short circuits will be achieved and proper functioning of the electrical system is provided

How to use this template?

Click on Use this template to open the diagram.

Once the template has opened, look for the Libraries panel on the left side. There you can find all the electrical components that you might want to add in. Drag and drop the needed symbols onto your canvas.

Under Electrical Engineering, expand the Basic Electrical category. You can swap components, adjust values, and even add labels to tailor the circuit. You can also change line styles, colors, and text fonts for better clarity.

Now click File > Export and choose your preferred format (e.g., image file, PDF, SVG) to share and export to the diagram.

Why make a Powerstroke alternator wiring diagram

Using a detailed wiring diagram for a 7.3 Powerstroke alternator system provides numerous practical advantages for anyone involved in maintaining, repairing, or upgrading the vehicle's electrical components.

For instance, the use of the diagram makes it easy to find a simplified representation of the electric system that serves as a map that illustrates the connection of all the parts of the car and how they are all linked. These are some of the significant components of the automobile and they include the battery, starter relay, alternator, instrument cluster and charge indicator, fusible link, and fuse box.

These relationships are important to note in looking at the interprofessional relationships in the workforce with the idea of achieving the best level of adequacy in professionals tackling electrical issues.

For instance, there are times when a vehicle does not start, or the battery is not charged appropriately; this means professionals in mechanic and technician fields will be required to look at the wiring diagram if they are to understand the flow of the circuit and follow it as well as look at the possibility of having errors and troubleshooting where necessary.

Secondly, due to its usage in the wiring of circuits, the wiring diagram can be helpful in other complex electrical problems that an individual may never even detect without the wiring diagram. This is not a very uncommon scenario where because of weak electrical system mapping one gets lost between the facilities while trying to find flaws.

Frequently asked questions

-

How many amps is a 7.3 Powerstroke alternator?

The alternator on a 7.3 Power Stroke diesel engine typically outputs around 130 amps. This level of current generation is sufficient to power the vehicle's electrical systems and accessories while also charging the battery.

-

How many volts does it take to start a 7.3 Powerstroke?

Starting a 7.3 Powerstroke diesel engine usually is appropriately charged and needs at least 12 volts. This voltage is necessary to provide sufficient current to the starter motor which brings the crankshaft of the engine into motion and subsequently ignites the mixture.

-

What is the ICP on a 7.3 Powerstroke?

The Injection Control Pressure (ICP) sensor on a 7.3 Powerstroke Diesel engine is responsible for monitoring hydraulic pressure within the High-pressure oil system. It is crucial to maintain this pressure to provide accurate and optimized injection of fuel into the engine, which heavily influences its performance and fuel consumption.

Related templates

Get started with EdrawMax today

Create 210 types of diagrams online for free.

Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free