- All templates

- Activity diagram templates

- Activity diagram supply chain system

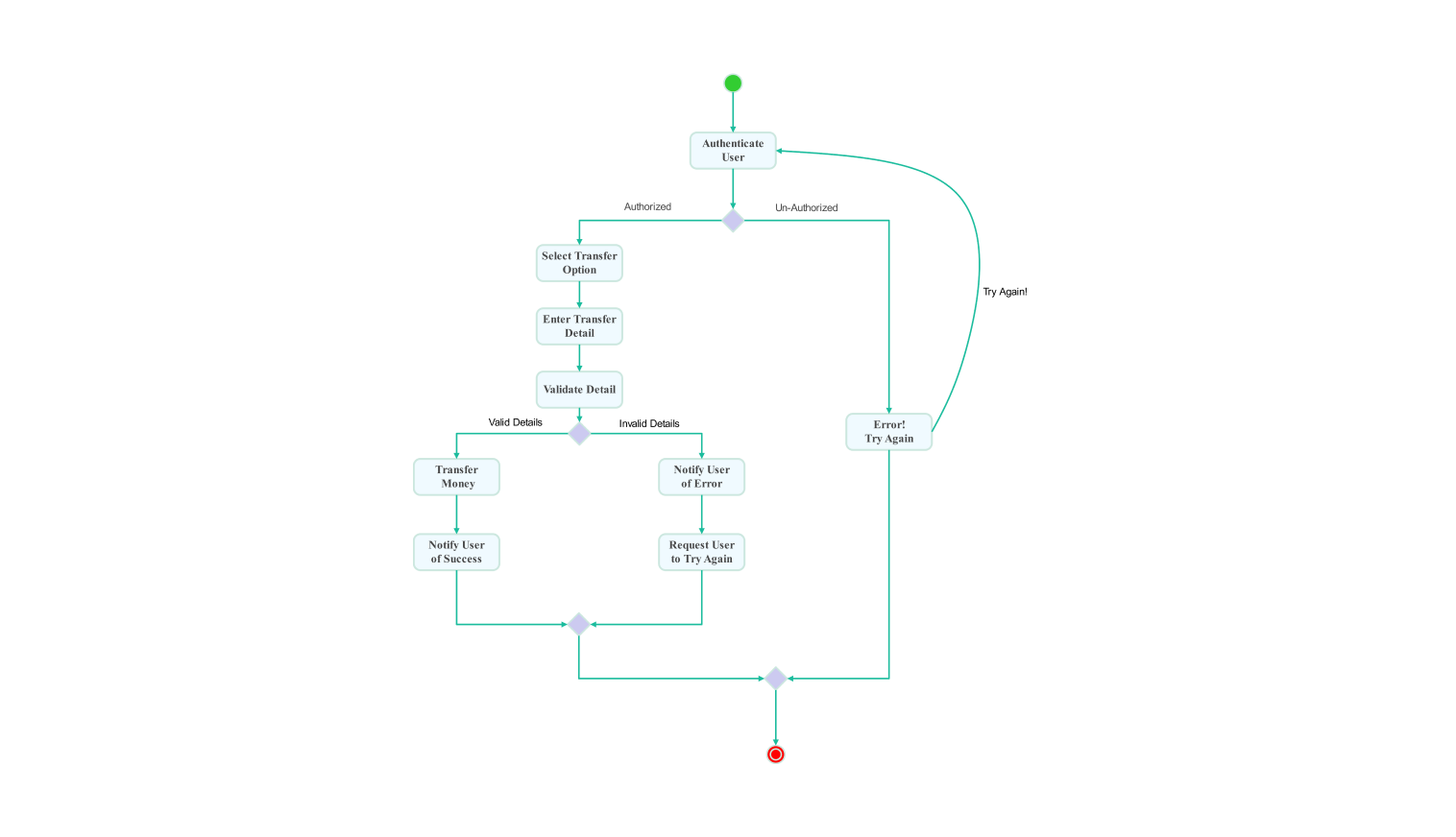

About this activity diagram for the supply chain system

The UML activity diagram for the supply chain system shows a system that efficiently manages orders from suppliers to customers. It also ensures proper stock management, quick order delivery, and customer satisfaction.

This supply chain process starts with supplier management. It's vital for onboarding trustworthy suppliers who can deliver products as promised. This step may include checking suppliers on their prices, quality, delivery time, and reliability. Effective supplier management is key to a strong supply chain. It reduces the risk of interruptions.

Once suppliers are selected, the system creates an order for the supplier. This is where an order is placed to state the products that are needed either to replenish stock or to meet a customer’s order. This activity might be specific. It includes the needed quantities, the delivery timeline, and any unique specs for the items.

After formulating an order, it goes to an approval point. This is a key step after the order is processed. Here, management or an automated system dissects the order information.

Approval to place the order is allowed if it meets several factors. These include the availability of funds, projected sales, and current inventory levels. If it is not approved, the order goes to the revised order section. There, it will be changed to meet the approval standards. Upon order approval, it activates fulfillment. This involves preparing goods for delivery. It covers the order's correctness, the packing standard, and any client needs or legal requirements.

Fulfillment is three-dimensional in shipping. It means loading the specified goods and delivering them on time. Shipping companies or the logistics department perform this step. They must ensure all orders are delivered on time and correctly.

Once the items are dispatched, updated inventory synchronously adjusts the stock on hand. It accounts for received items and products flown out. It is very important to keep accurate inventory records. This prevents stock-outs or excess stock. Then, after the inventory updates, the order advances to "order sent to customers." All conditions for fulfillment are met, and the order is delivered to the proper addresses.

Finally, gathering feedback is valuable. It helps gauge customer service, find supply chain gaps, and fix them if needed. Feedback loops help the supply chain system improve processes and fix issues. This is key to winning in business. Here the UML activity diagram for the supply chain system helps to ensure that the supply chain process runs smoothly and is error-free.

Related templates

Get started with EdrawMax today

Create 210 types of diagrams online for free.

Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free