Supply chain risk is the potential disruption or negative impact on a company's supply chain operations. The types of supply chain risks can arise from various factors, ranging from financial instability to compliance issues, environmental concerns, geopolitical uncertainties, and cyber threats.

Supply chain risk encompasses any potential harm or disruption that can affect the smooth functioning of a company's supply chain. It primarily revolves around the uncertainty and vulnerability associated with the flow of goods, services, and information between suppliers, manufacturers, distributors, and customers.

Understanding and effectively managing the various types of supply chain risks is crucial for businesses to maintain operational resilience and ensure uninterrupted supply chain operations.

In this article

Part 1. Types of Supply Chain Risks

There are various types of supply chain risks. It is crucial for organizations to mitigate these risks.

- Financial Risks: Financial risks refer to uncertainties arising from economic factors such as exchange rate fluctuations, credit risks, liquidity issues, or the financial instability of supply chain partners.

- Compliance/Legal Risks: Compliance and legal risks involve the potential non-compliance with various laws, regulations, and industry standards.

- Environmental Risks: Environmental risks arise from the impact of unpredictable natural calamities, climate change, and sustainability concerns on the supply chain.

- Geopolitical Risks: Geopolitical risks stem from political instability, trade disputes, and changes in government policies, terrorism, or civil unrest.

- Cyber Risks: Cyber supply chainrisks refer to the threats arising from unauthorized access, data breaches, intellectual property theft, or disruptions to information systems.

- Logistics Risks: Logistics risks involve challenges related to transportation, warehousing, and distribution.

- Workforce Risks: Workforce risks pertain to the uncertainties arising from labor shortages, talent gaps, or labor-related disputes.

Part 2. Best Practices to Mitigate Supply Chain Risks

Mitigation of supply chain risks is important. There are some best practices that should be adhered to when mitigating supply chain risks.

- Identify and Evaluate: To effectively mitigate supply chain risks, companies must first identify and evaluate potential risks within their supply chain network.

- Prioritize: After identifying risks, it is essential to prioritize them based on their likelihood and potential impact.

- Honesty is the Best Policy: Maintaining transparency and open communication with supply chain partners is crucial for effective risk mitigation.

- Never Stop Learning: Supply chain risks are constantly evolving, and it's vital to continuously learn and adapt.

The Supply Chain National Institute of Standards and Technology (NIST) is an initiative that offers guidelines and standards to enhance supply chain security and resilience. NIST supply chain aims to help organizations identify, assess, and mitigate supply chain risks by providing a systematic framework and best practices.

Part 3. What are the 5 Components of NIST?

There are five key components of Supply Chain NIST. All of these components are extremely important.

- Identify: Understanding the critical components of the supply chain and identifying potential risks and vulnerabilities associated with them.

- Protect: Implementing measures to safeguard sensitive data, assets, and operations from potential threats or disruptions.

- Detect: Employing mechanisms to detect and monitor any suspicious activities or anomalies within the supply chain.

- Respond: Establishing plans and procedures to respond promptly and effectively to supply chain disruptions, minimizing their impact.

- Recover: Developing strategies to restore supply chain operations swiftly and efficiently after a disruption, ensuring minimal downtime and restoring normalcy.

Part 4. Make a Supply Chain Risk Management Flowchart with EdrawMax

A flowchart can be a helpful tool for understanding the types of risk in supply chain management and ways to mitigate them. Wondershare EdrawMax has versatile templates specifically designed to help create such flowcharts. Given below are the steps to create such a flowchart using the tool:

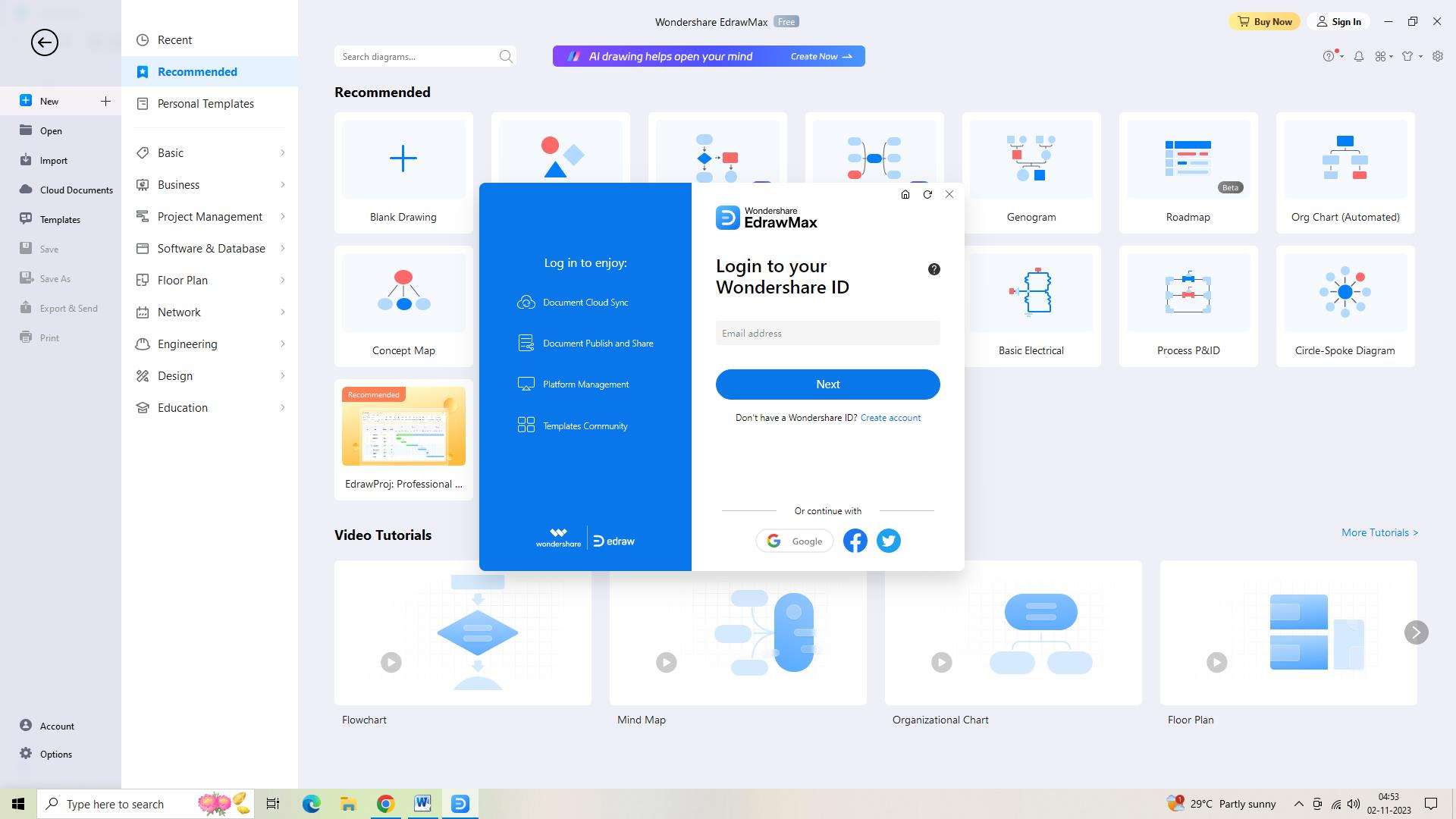

Step 1: Sign in to Wondershare Edrawmax

The first step is to sign in to the EdrawMax platform. Log in using your email address and password or via a social media or Google account.

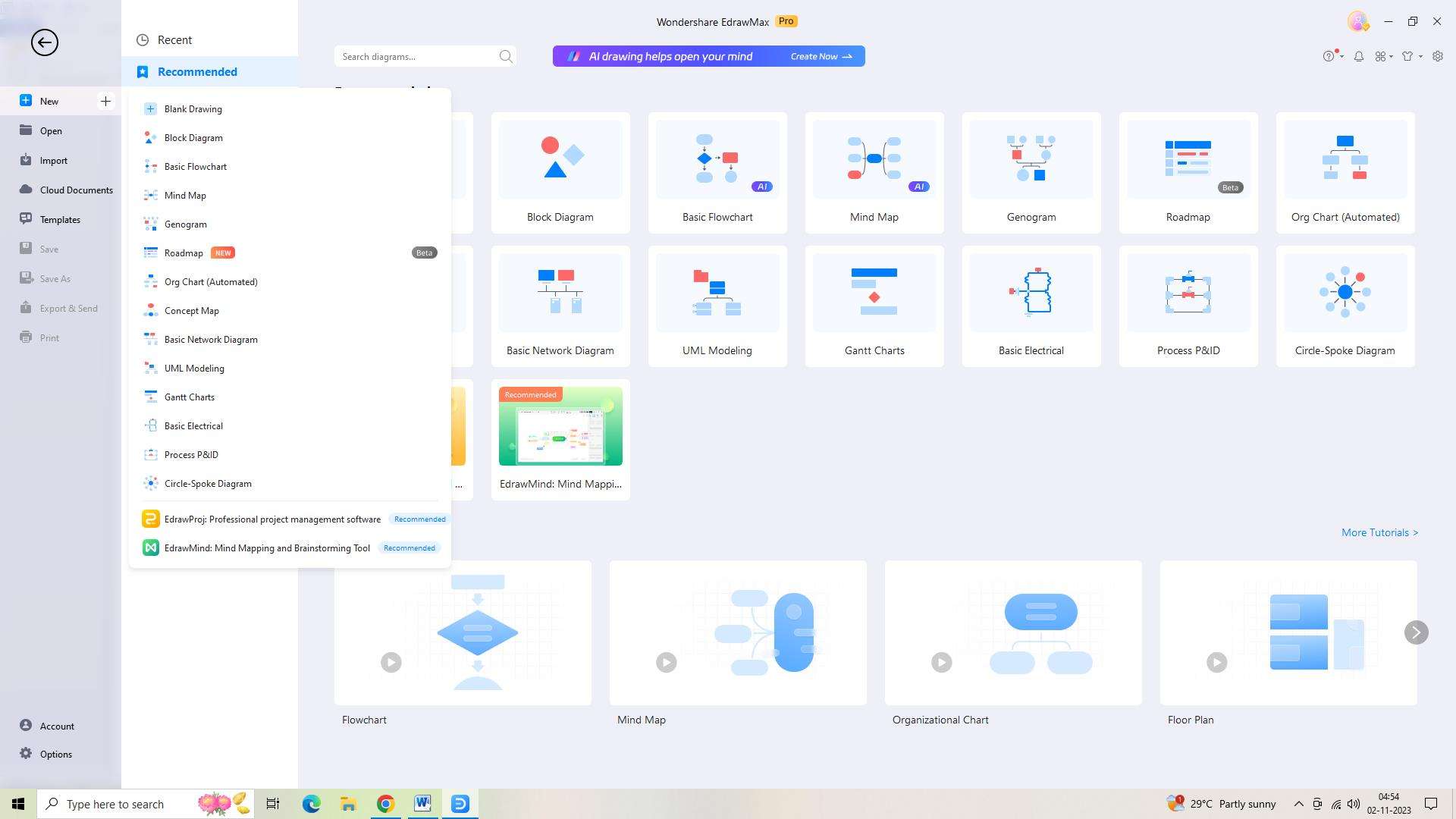

Step 2: Open a New Document

Once signed in, open a new document. To do so, click the plus symbol to the right of the "New" button.

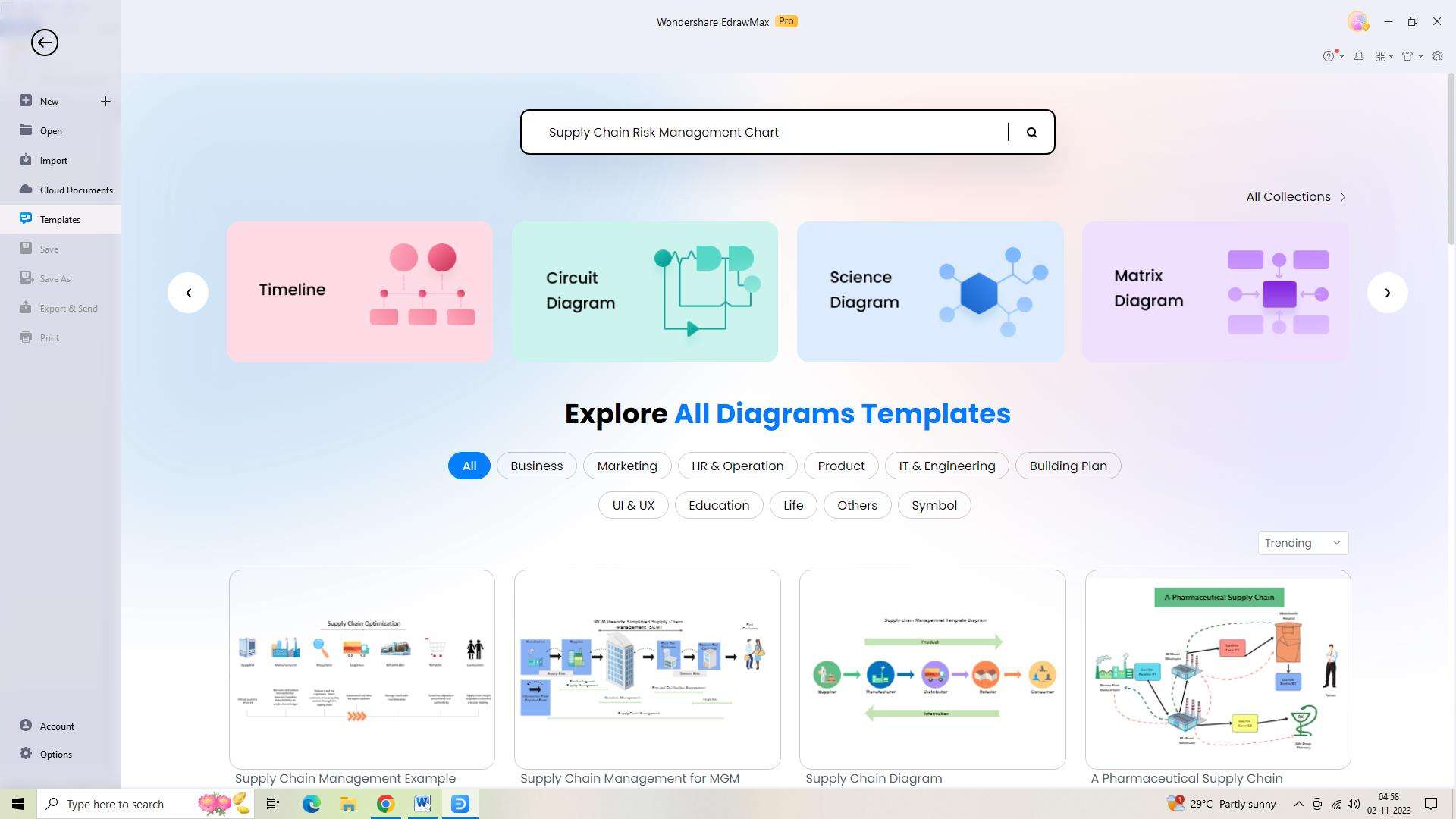

Step 3: Search for a Template

Now, search for the “Supply Chain Risk Management Chart” template in the “Templates” section. Select it to open it.

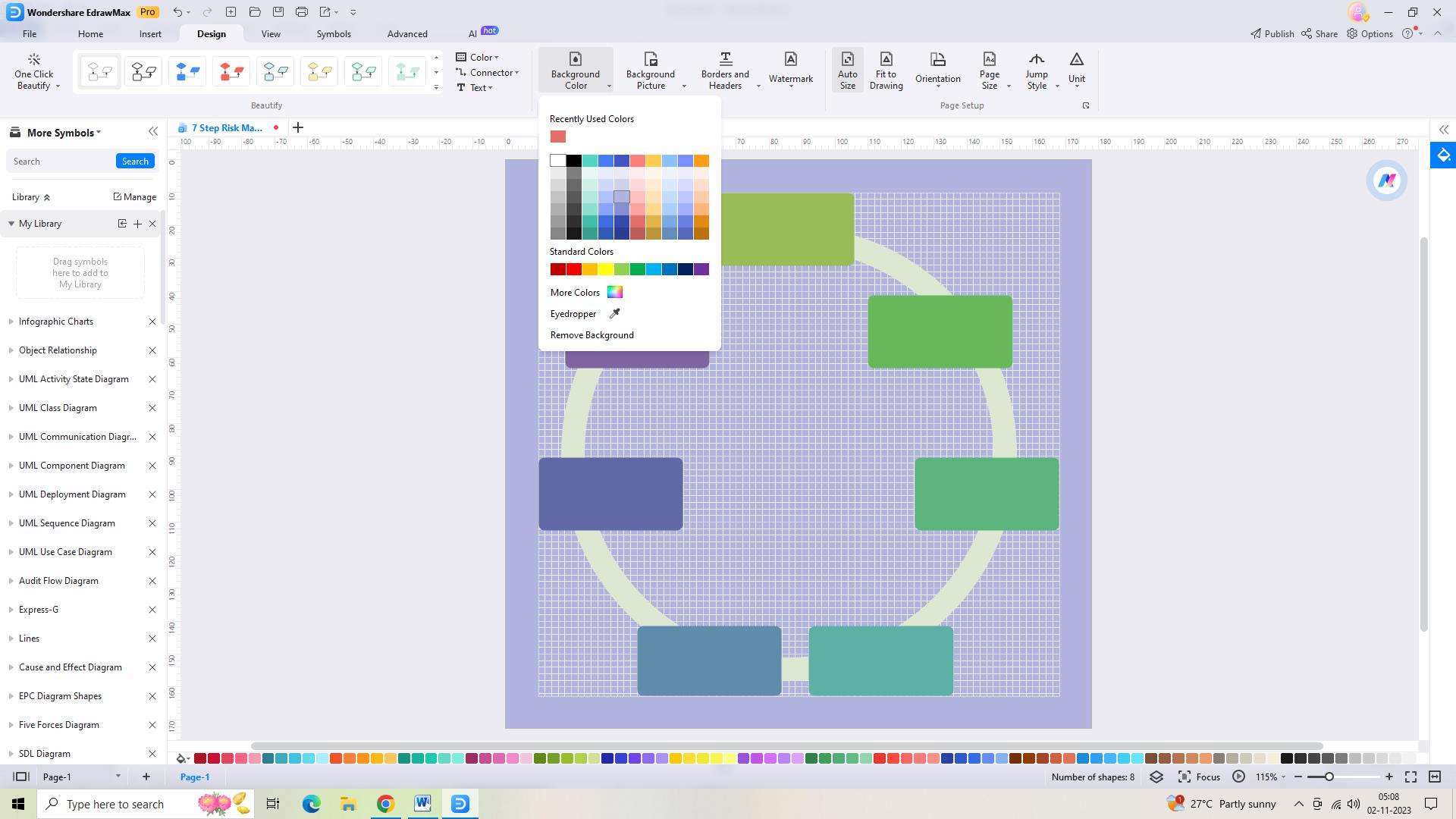

Step 4: Personalize the Template

Once the template appears, you can further personalize it by adding colors, shapes, and other graphics. Drag and drop these onto the canvas as you create your desired flowchart.

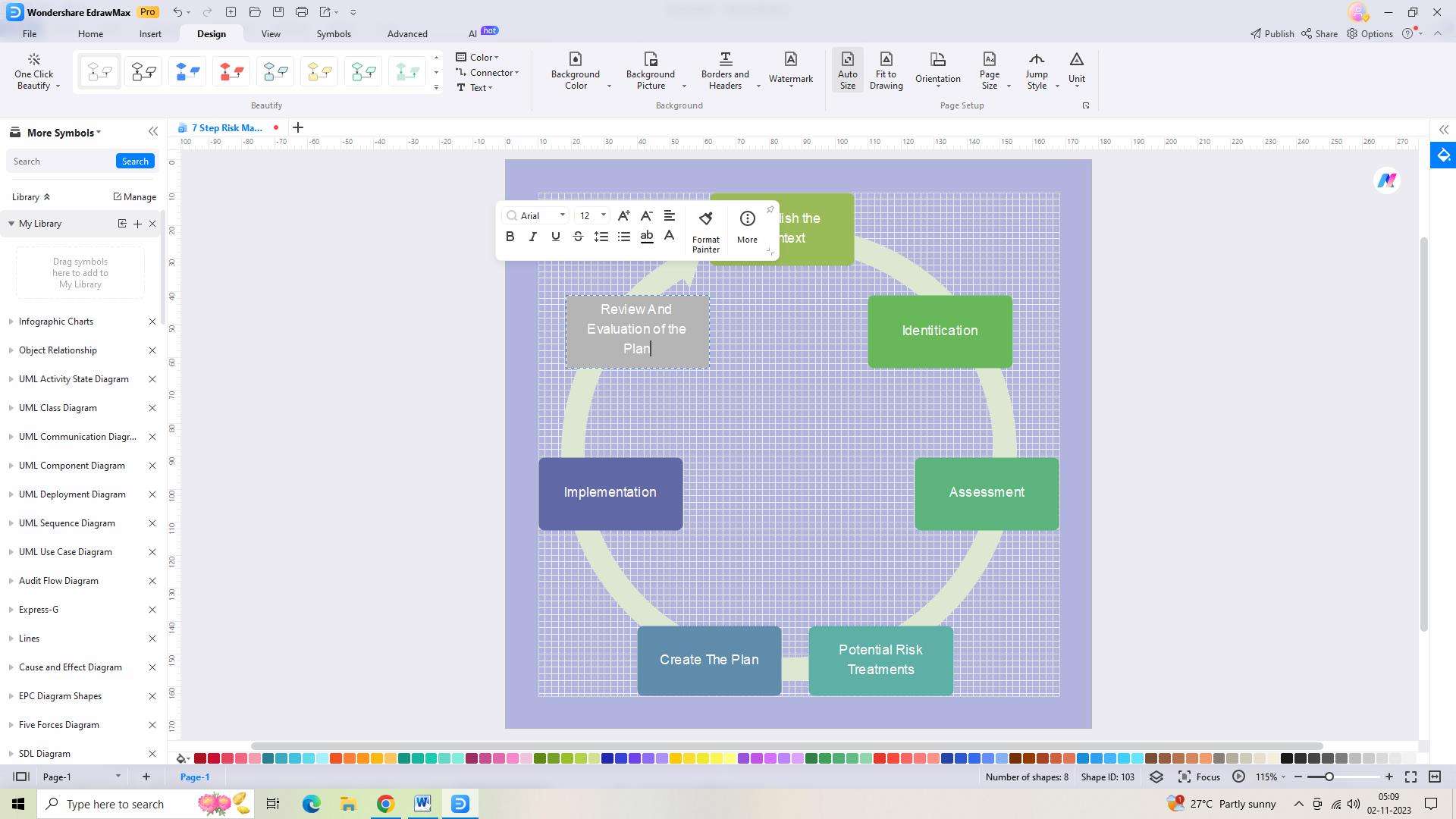

Step 5: Add Data to the Flowchart

Now, add data to the flowchart. This could be any information regarding the supply chain, from the goods and services involved to their transfer locations and risks.

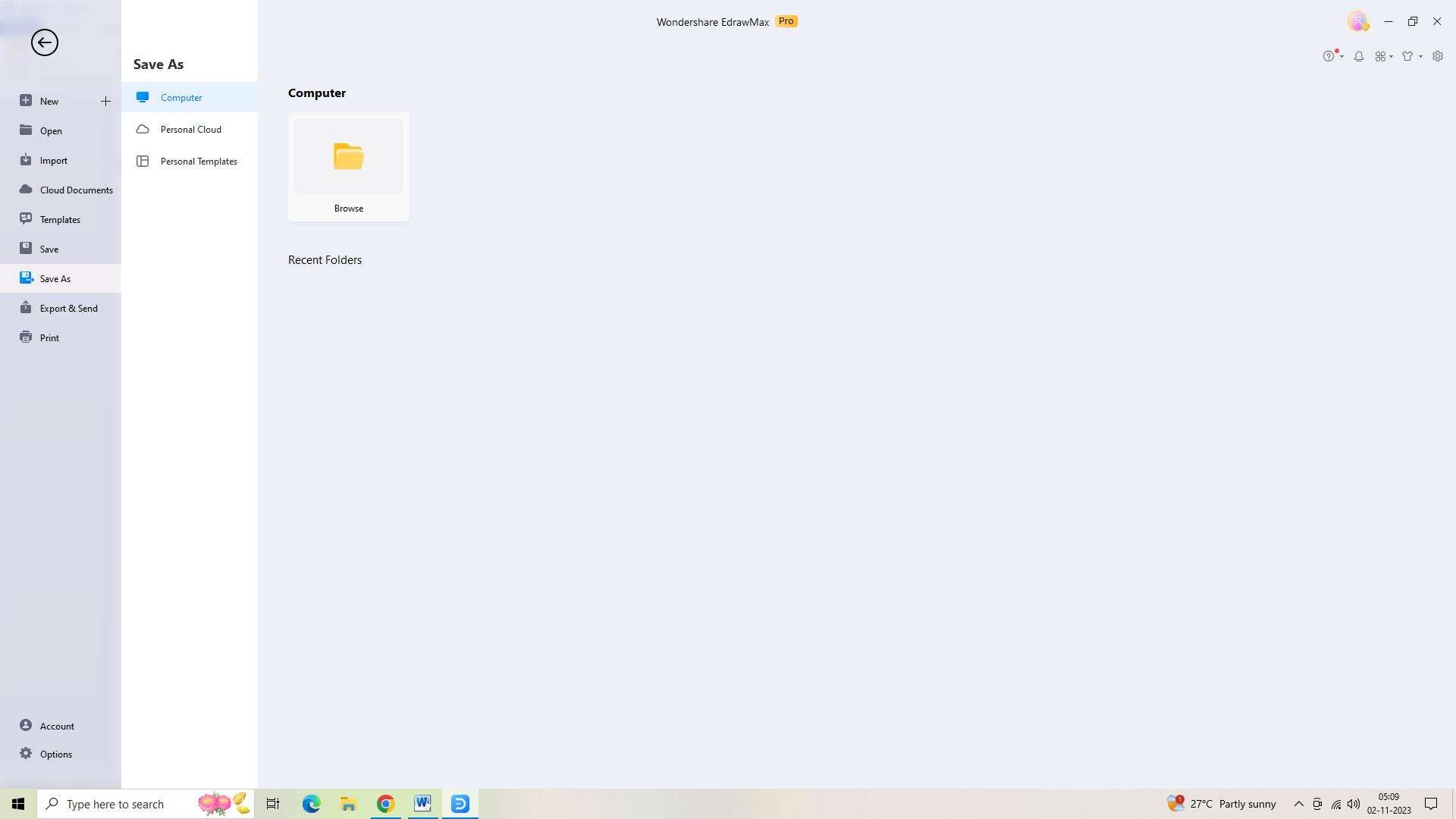

Step 6: Save the Flowchart

Once you’ve added the data and customized the flowchart to your preference, save the document by clicking on ‘Save’ in the file menu.

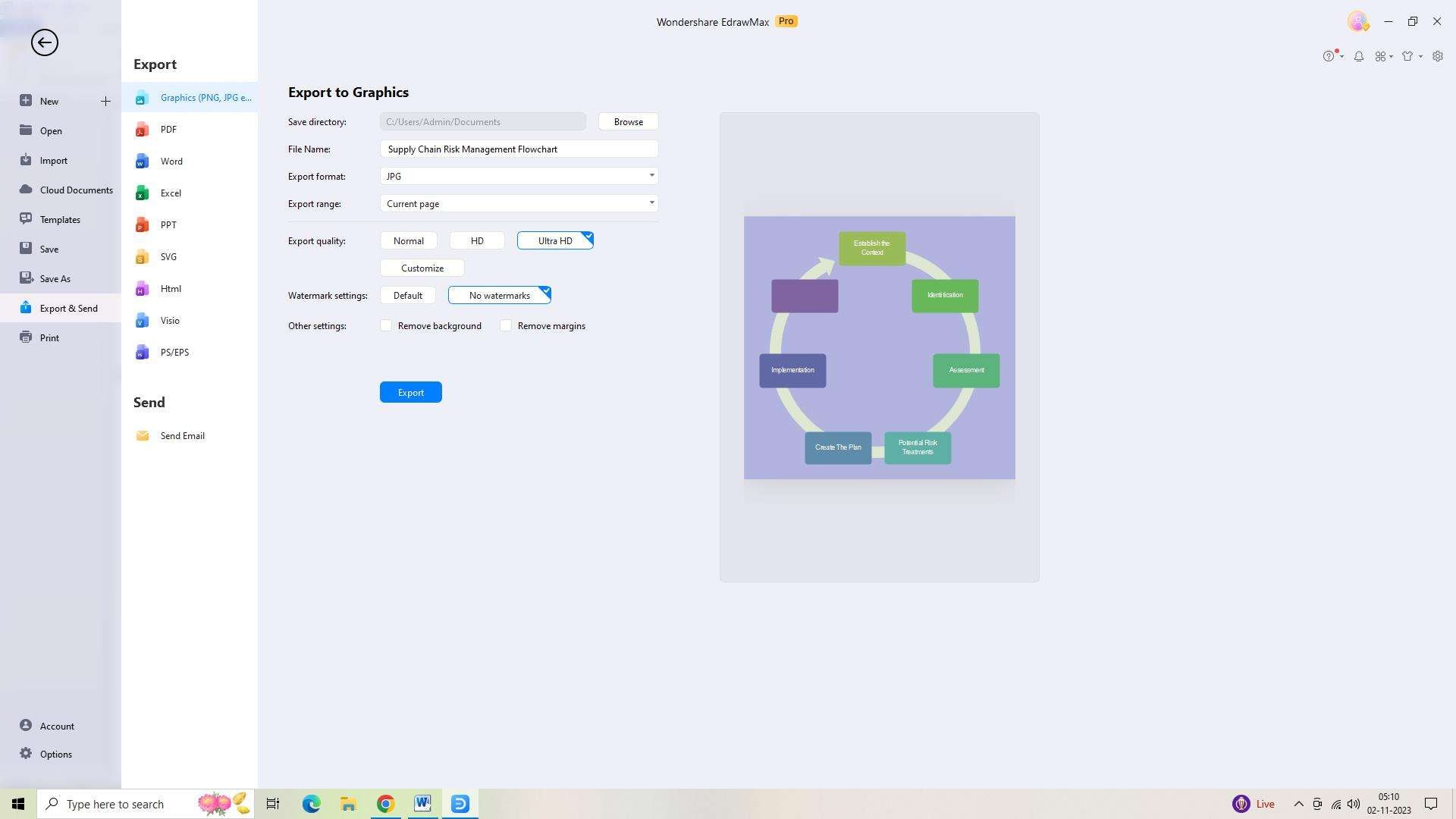

Step 7: Export the Flowchart

Lastly, export the flowchart by clicking on ‘Export’ in the file menu. Choose the desired format - such as PDF, PNG, or JPG - and save the file to your device.

Final Thought

Supply chain risk can have significant implications for businesses. By understanding the various types of supply chain risks, implementing best practices to mitigate them, and leveraging frameworks like the NIST Supply Chain, organizations can enhance their operational resilience and minimize the negative impact of potential disruptions.