Quality risk management is a crucial process for organizations to ensure the success and sustainability of their operations. By proactively identifying and addressing potential risks, businesses can minimize the likelihood of issues that could negatively impact their product quality, customer satisfaction, and reputation.

In this article

Part 1. The Importance of Quality Risk Management

Quality and risk management is a critical process that organizations must implement to ensure the success and sustainability of their operations. By proactively identifying and addressing potential risks, businesses can minimize the likelihood of issues arising that could negatively impact product quality and customer satisfaction.

1. Compliance:Quality risk management helps organizations meet regulatory requirements and industry standards, ensuring that products and services are in line with established guidelines.

2. Cost savings:By addressing potential risks early on, businesses can avoid costly recalls, rework, and customer complaints, resulting in significant cost savings.

3. Continuous improvement:Quality risk management encourages a culture of continuous improvement by identifying areas for enhancement and implementing necessary changes.

4. Reputation management:Effective risk management helps protect the organizational reputation by ensuring consistent delivery of high-quality products and services.

Part 2. Key Principles of Quality Risk Management

The key principles of quality risk management are implemented for managing qualitative risks. These principles aid in making certain that organizations can keep quality risks at bay. Most organizations adhere to these principles.

1. Risk assessment:Identify and evaluate potential risks associated with product quality, safety, and compliance.

2. Risk control:Implement measures to mitigate or eliminate identified risks.

3. Risk communication:Ensure effective communication of risks to relevant stakeholders.

4. Risk review:Regularly review and update risk management strategies to adapt to changing circumstances.

5. Proactive approach:Anticipate and address risks before they escalate.

6. Documentation:Maintain comprehensive documentation of risk management activities.

Part 3. Techniques for Identifying Quality Risks

Identifying quality risks is important. There exist some innovative techniques to identify quality risks. These techniques are unique for the quality risk management process, and utilizing these ensures that companies can spot qualitative risks easily.

1: Failure mode and effects analysis (FMEA): Systematically analyze potential failures and their impact on product quality.

2. Root cause analysis:Investigate the underlying causes of quality issues to identify potential risks.

3. Process mapping:Visualize the entire production process to identify areas where quality risks may occur.

4. Expert opinions:Seek insights from subject matter experts to identify potential risks.

5. Customer feedback analysis:Analyze customer complaints and feedback to identify recurring quality issues.

6. Benchmarking:Compare performance against industry standards to identify gaps and potential risks.

Part4. Strategies for Mitigating Quality Risks

Quality and risk management and mitigation need specialized strategies. Strategies that work for mitigating other types of risks may not necessarily work for quality risks. Using these strategies is important for organizations to guarantee that qualitative risks are mitigated efficiently and effectively.

1. Quality Control Implementation:Implement robust quality control measures throughout the production process.

2. Establishing Quality Standards:Establish clear quality standards and ensure adherence to them.

3. Training and Development Programs:Conduct regular training and development programs for employees to enhance their skills and knowledge. This is common for quality risk management in pharmaceutical industry.

4. Preventive Maintenance Programs:Implement preventive maintenance programs to minimize equipment failures.

5. Cultivating a Culture of Continuous Improvement:Foster a culture of continuous improvement and encourage employees to report potential risks.

6. Reviewing and Updating Risk Management Strategies:Regularly review and update risk management strategies to address emerging risks.

7. Effective Communication Channels:Establish effective communication channels to ensure timely reporting and resolution of quality issues.

8. Regular Audits for Compliance Monitoring:Conduct regular audits to monitor compliance with quality standards and identify potential risks.

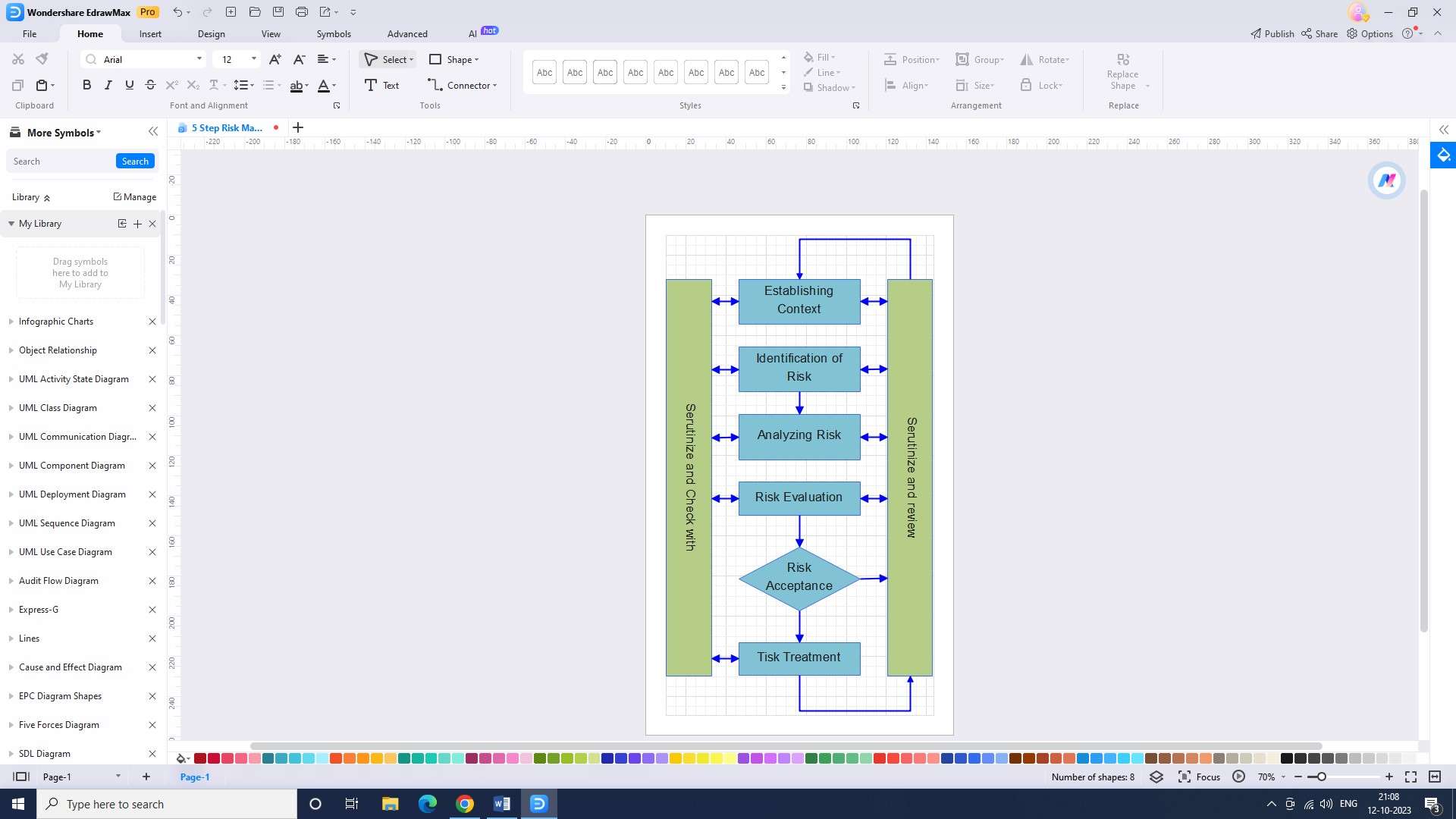

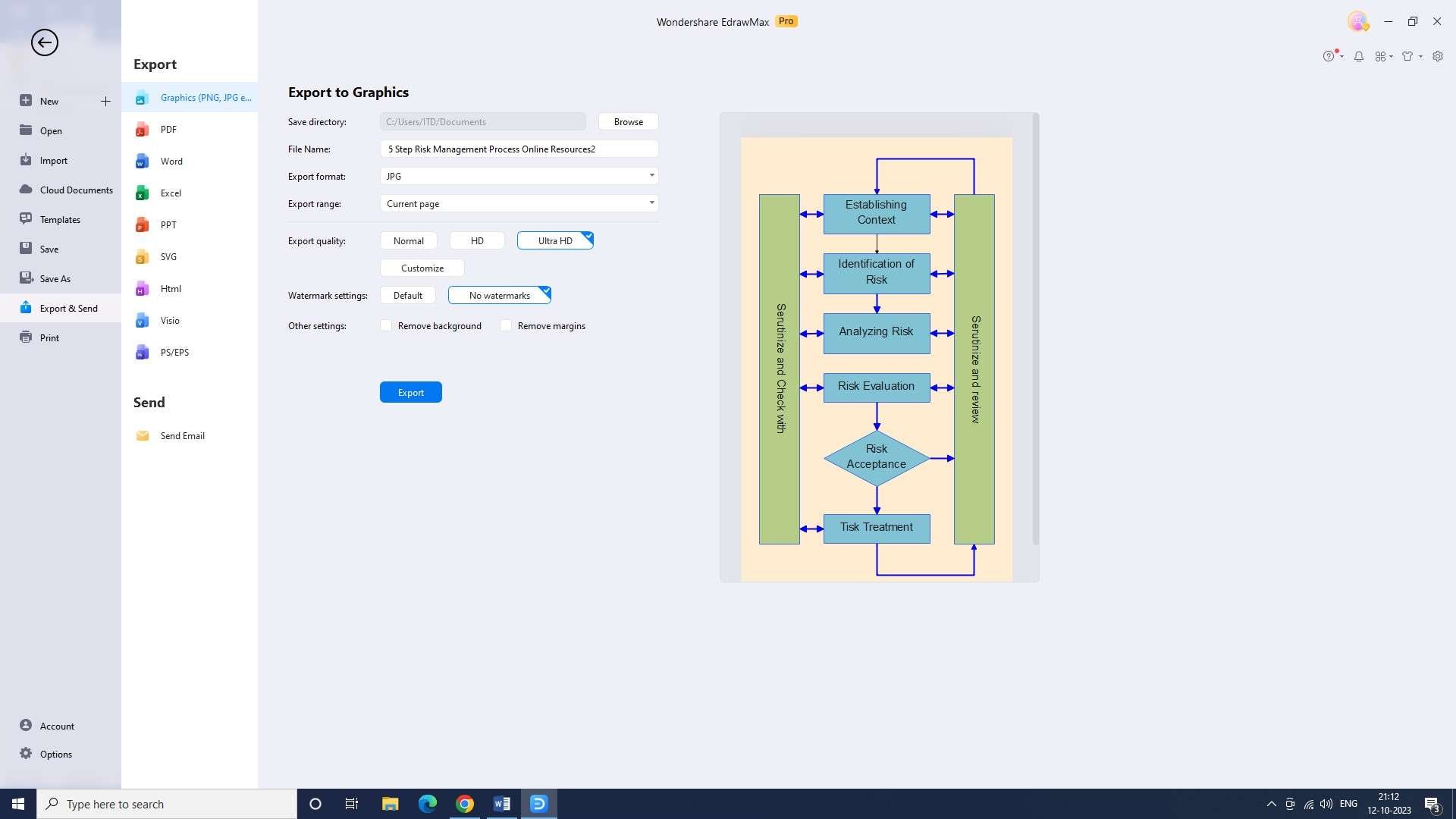

Part 5. Making a Risk Management Flowchart With EdrawMax

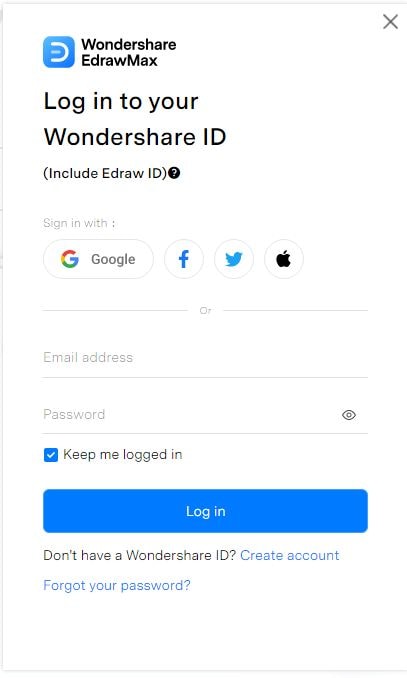

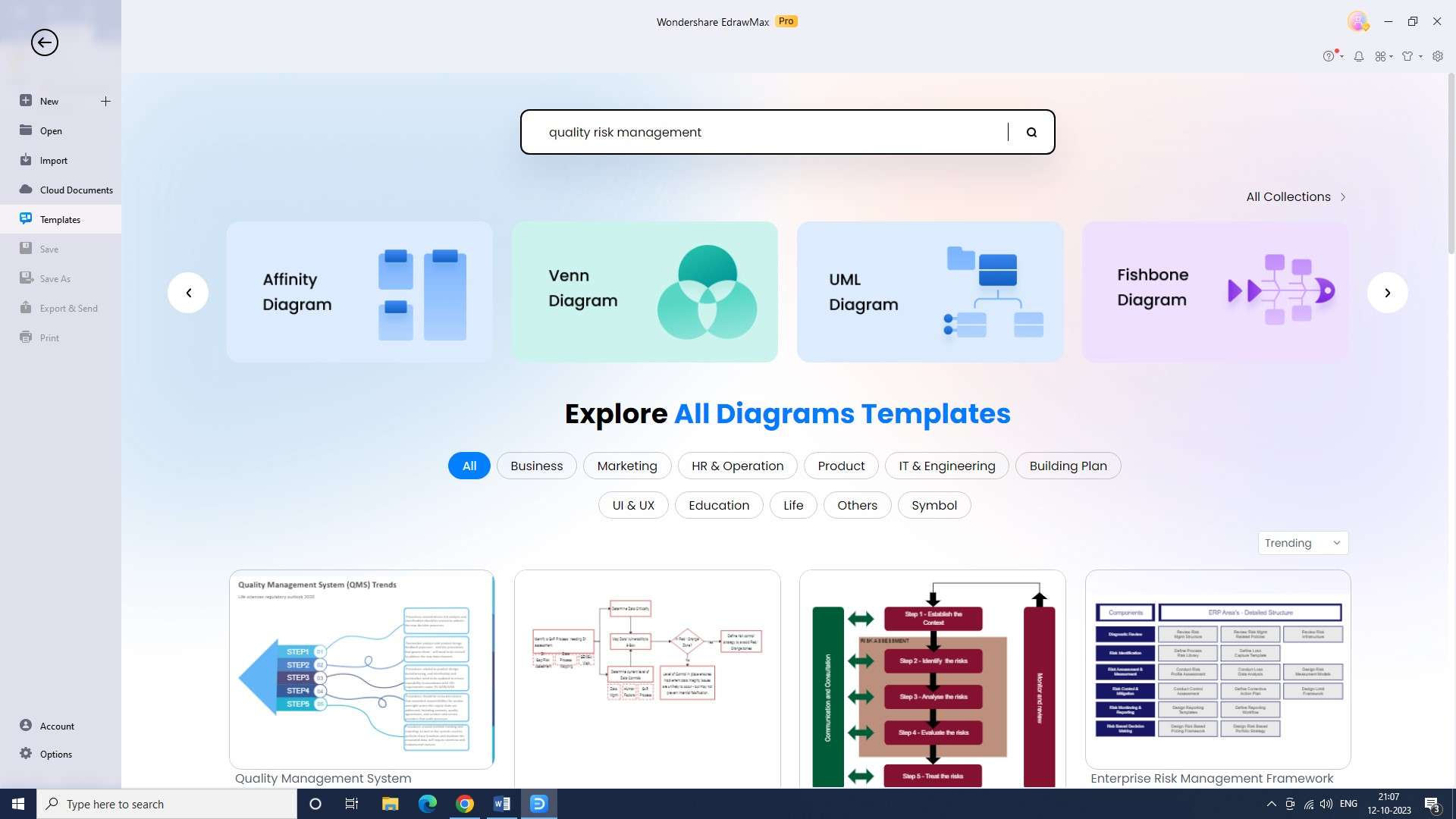

A reliable and user-friendly tool for making effective risk management charts is Wondershare EdrawMax. It enables users to quickly view and assess possible risks in any project or organization thanks to a large selection of templates and configurable components. Professionals seeking to efficiently manage and reduce risks in their businesses will find its easy interface and extensive functionality to be a vital tool. The steps to create a quality risk management flowchart using the tool are:

Step 1: Identify a suitable flowchart template

Look for a flowchart template specifically designed for quality risk management. You can find templates a huge collection of templates within EdrawMax.

Step 2: Open the template

Open the template within EdrawMax. Now, you can start working on your flowchart.

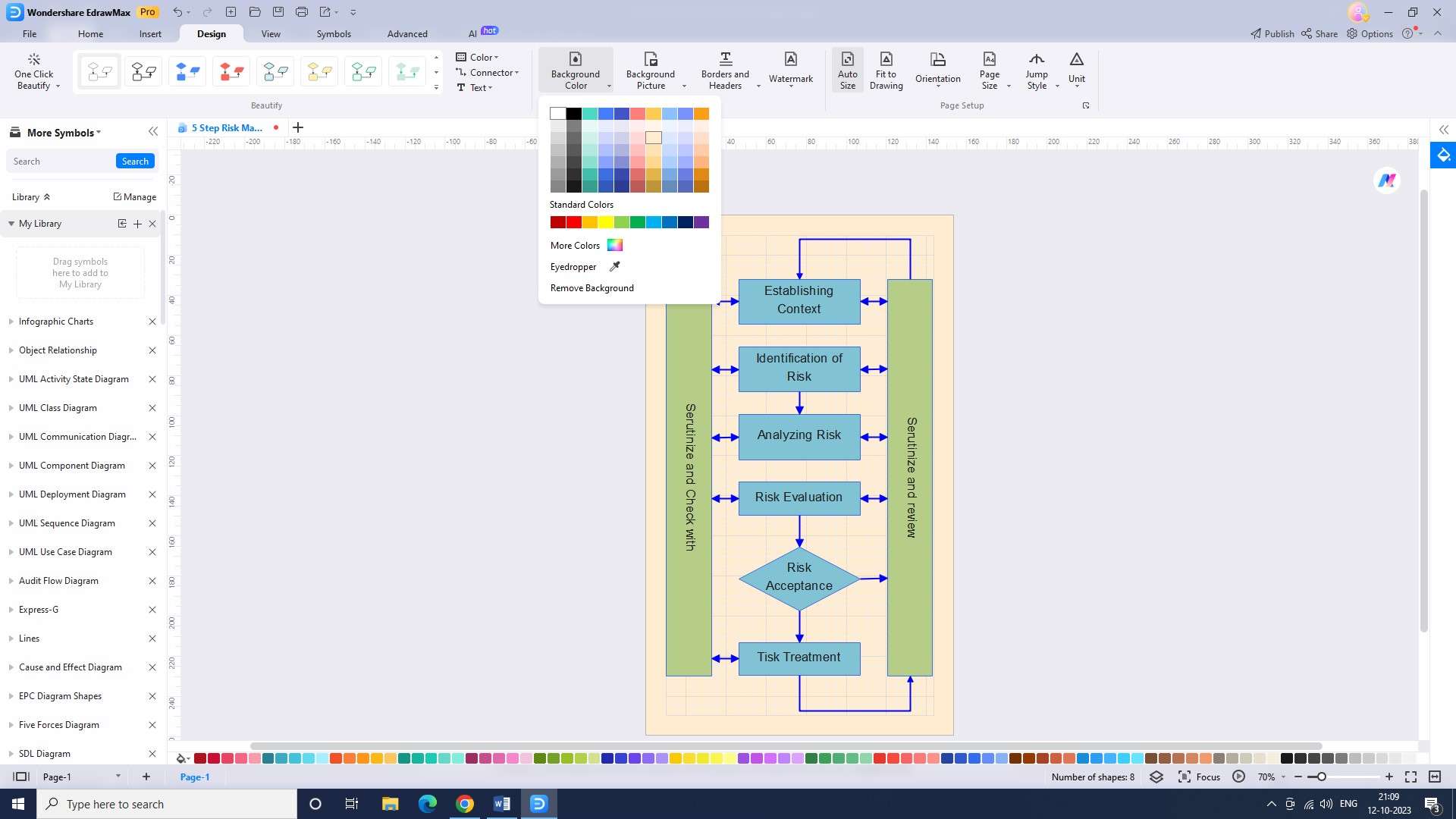

Step 3: Customize the template

Modify the template to fit your specific requirements. Replace the placeholder text, symbols, and shapes with the relevant information and elements of your quality risk management process.

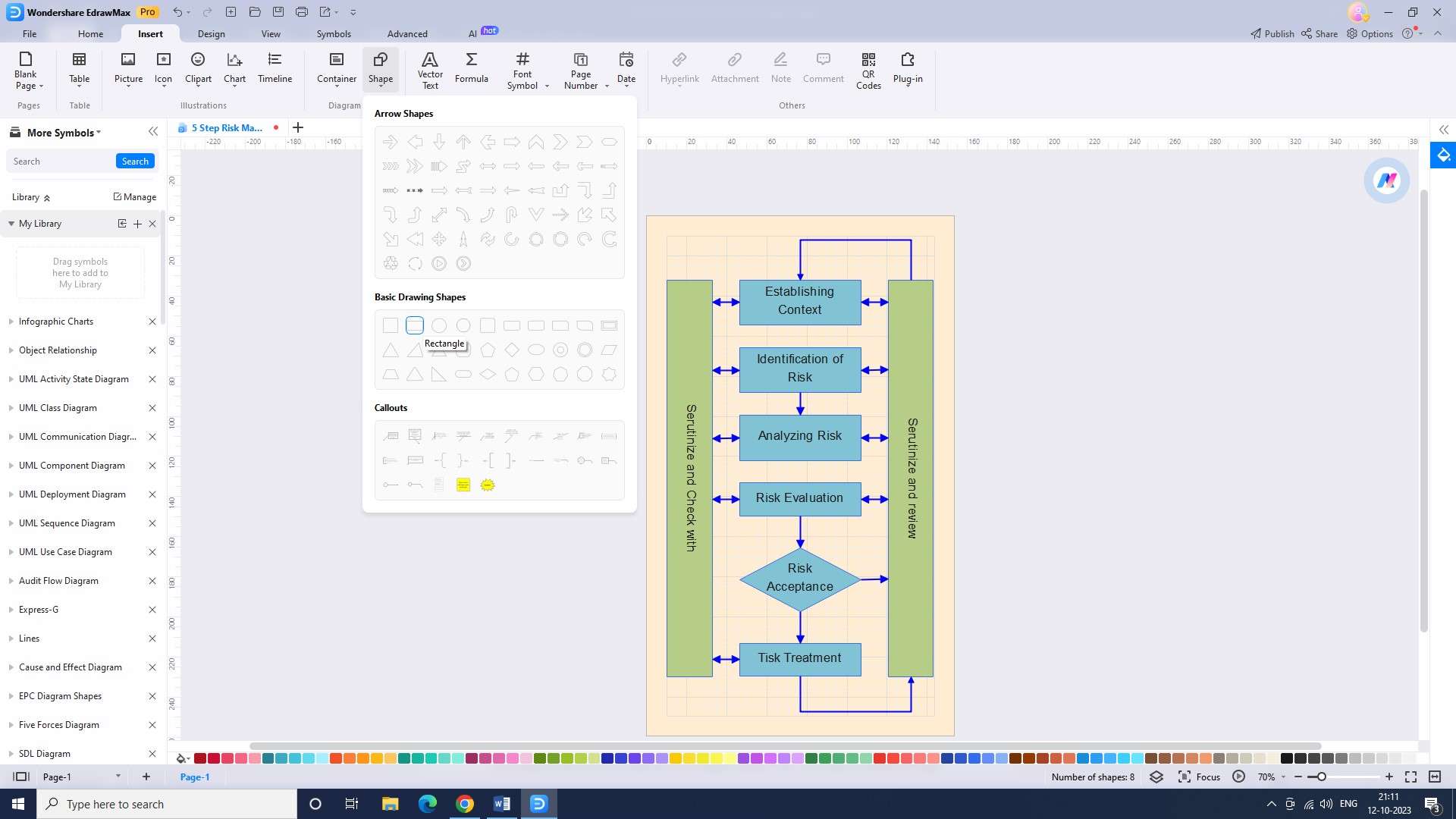

Step 4: Add decision points and risk assessment steps

If the template does not already include decision points and risk assessment steps, insert them into the flowchart. Use the appropriate symbols or shapes to represent these elements.

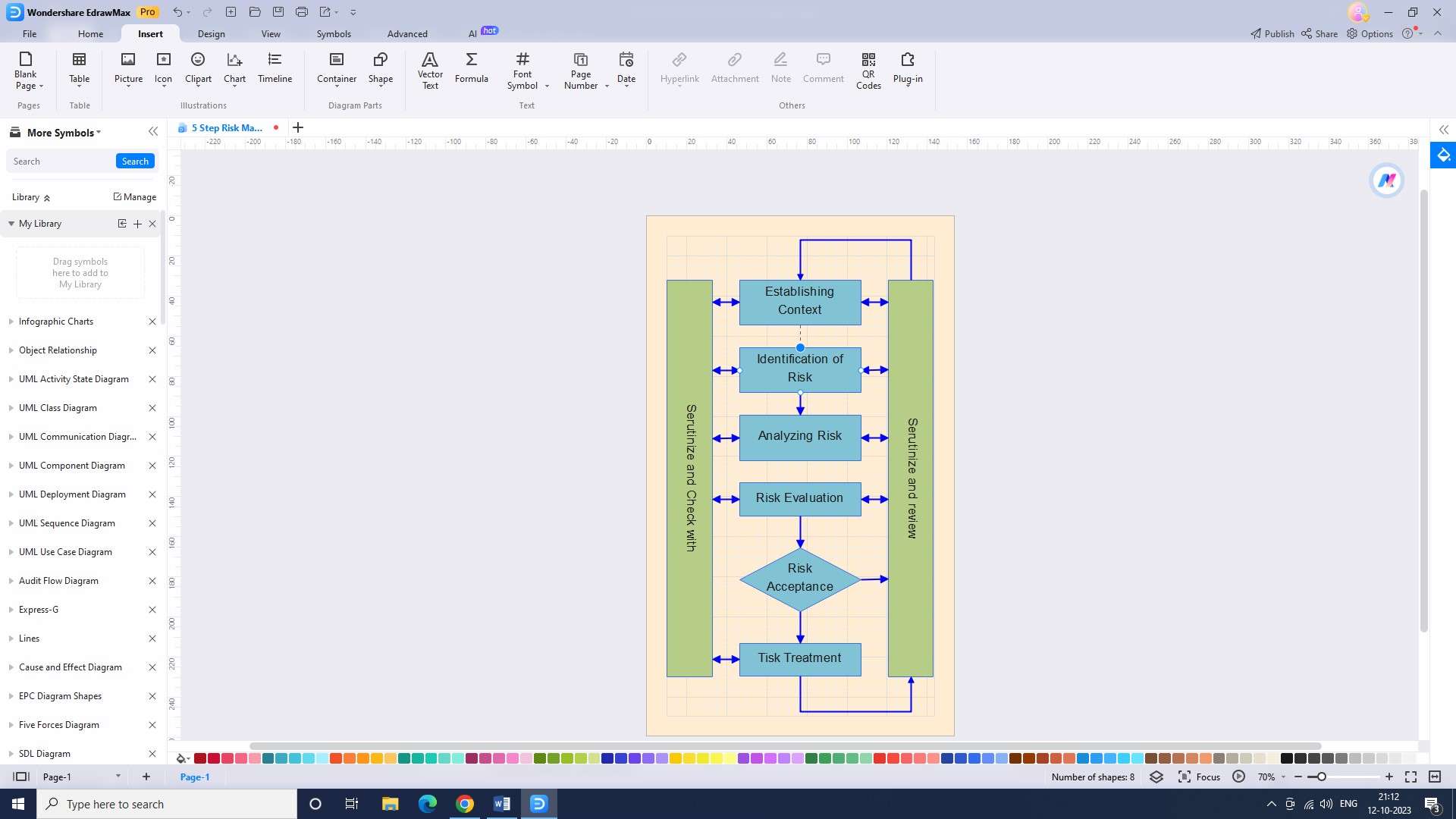

Step 5: Connect the flowchart elements

Use arrows or connectors to connect the symbols and decision points in the flowchart. Ensure that the connections accurately represent the sequence and flow of the quality and risk management process.

Step 6: Export the flowchart

Once you have completed the flowchart, export it in a suitable file format, such as PDF, PNG, or JPEG. Choose the option to export the flowchart from EdrawMax and save it to your desired location on your computer.

Conclusion

Implementing effective quality and risk management strategies is essential for organizations to maintain compliance, achieve cost savings, drive continuous improvement, and protect their reputation. By adhering to key principles and utilizing innovative techniques, businesses can identify and mitigate quality risks, ensuring the delivery of high-quality products and services.