- All templates

- Wiring diagram templates

- Delco Remy alternator wiring diagram

About this template

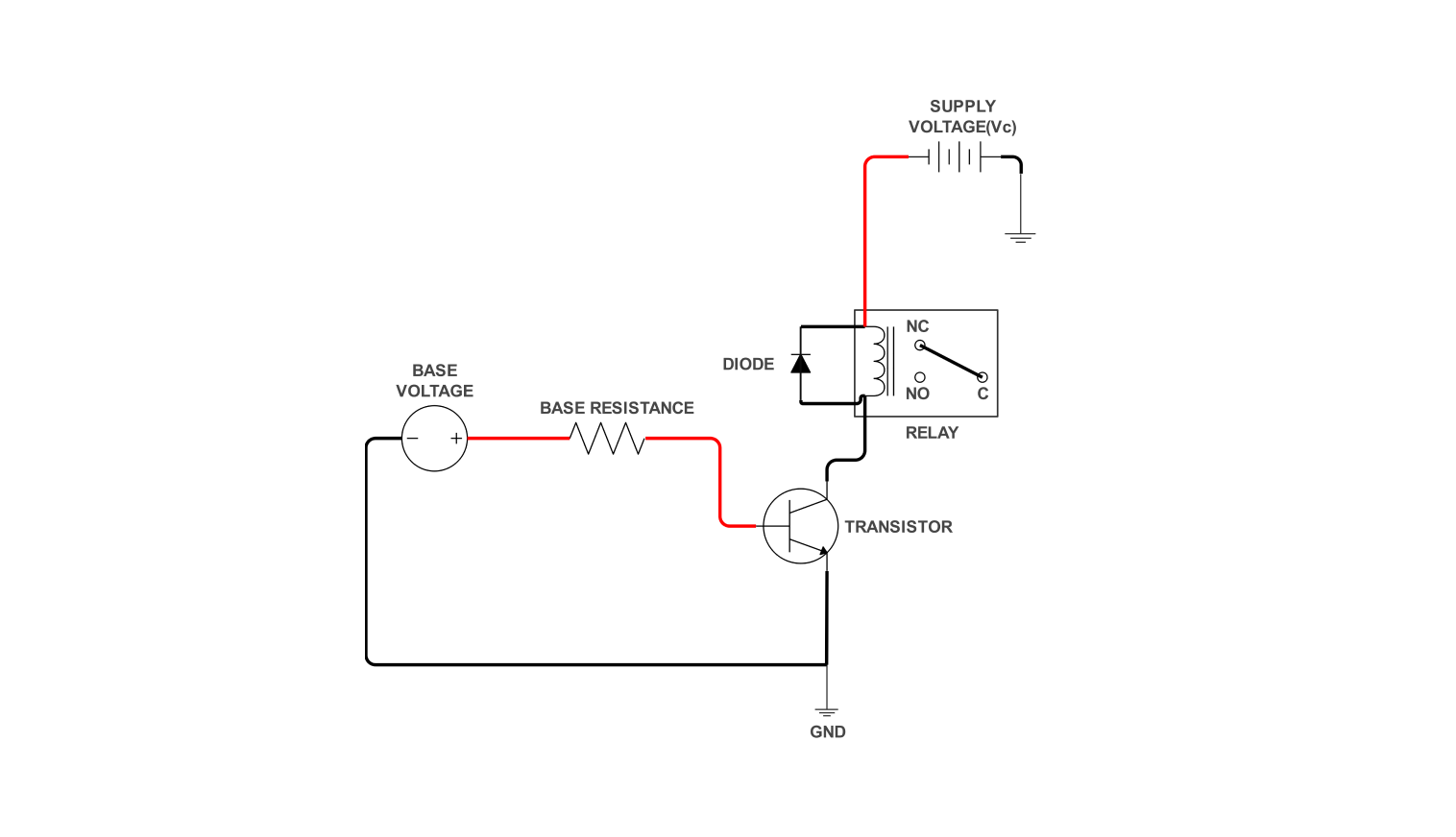

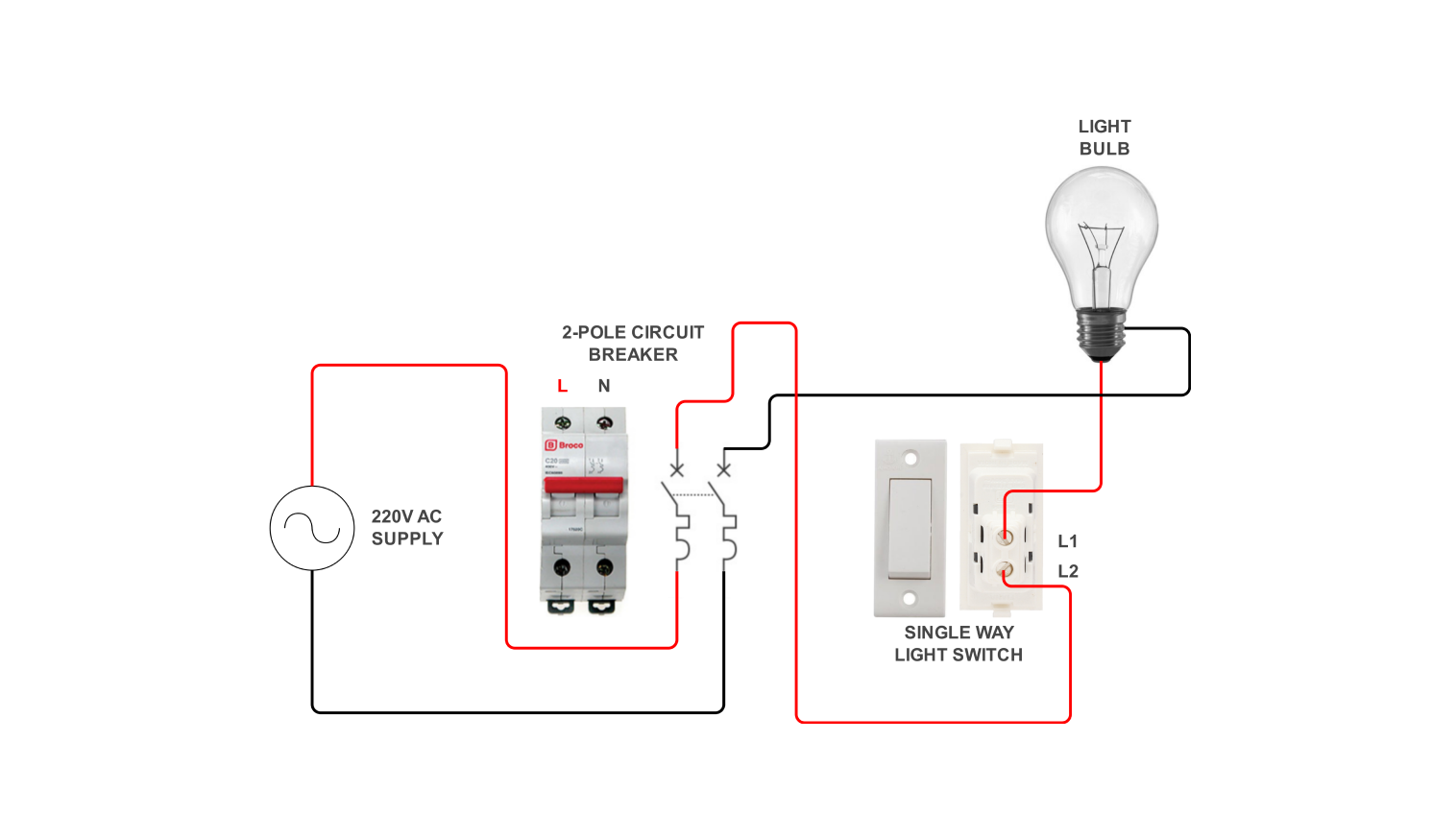

This wiring diagram refers to the setup of the connection between different components within a car particularly concerning the Delco Remy alternator to provide a functional circuit. This particular diagram places the Delcotron alternator at its hub; they are used to deliver mechanical energy from the engine and transform it to electrical energy.

They needed this power to charge the vehicle battery and supply power to other related systems. The instrument cluster is also present in the diagram, and its function is to provide the necessary data regarding the car's performance and possible problems. The controlling device of the starter is the ignition switch through which the engine begins; the starter solenoid on the other hand plays the role of transmitting current.

The fuse ratings are connected within the above diagram and are vital links that guard against overload within the systems. Moreover, the voltage regulator is an important component where it is responsible for regulating and providing a consistent output voltage from the alternator to the battery and electrical appliances. A junction block is essentially a unit that is used in the distribution of electrical power and the making of joints to the circuit.

How to use this template?

Click on Use this template to open the diagram.

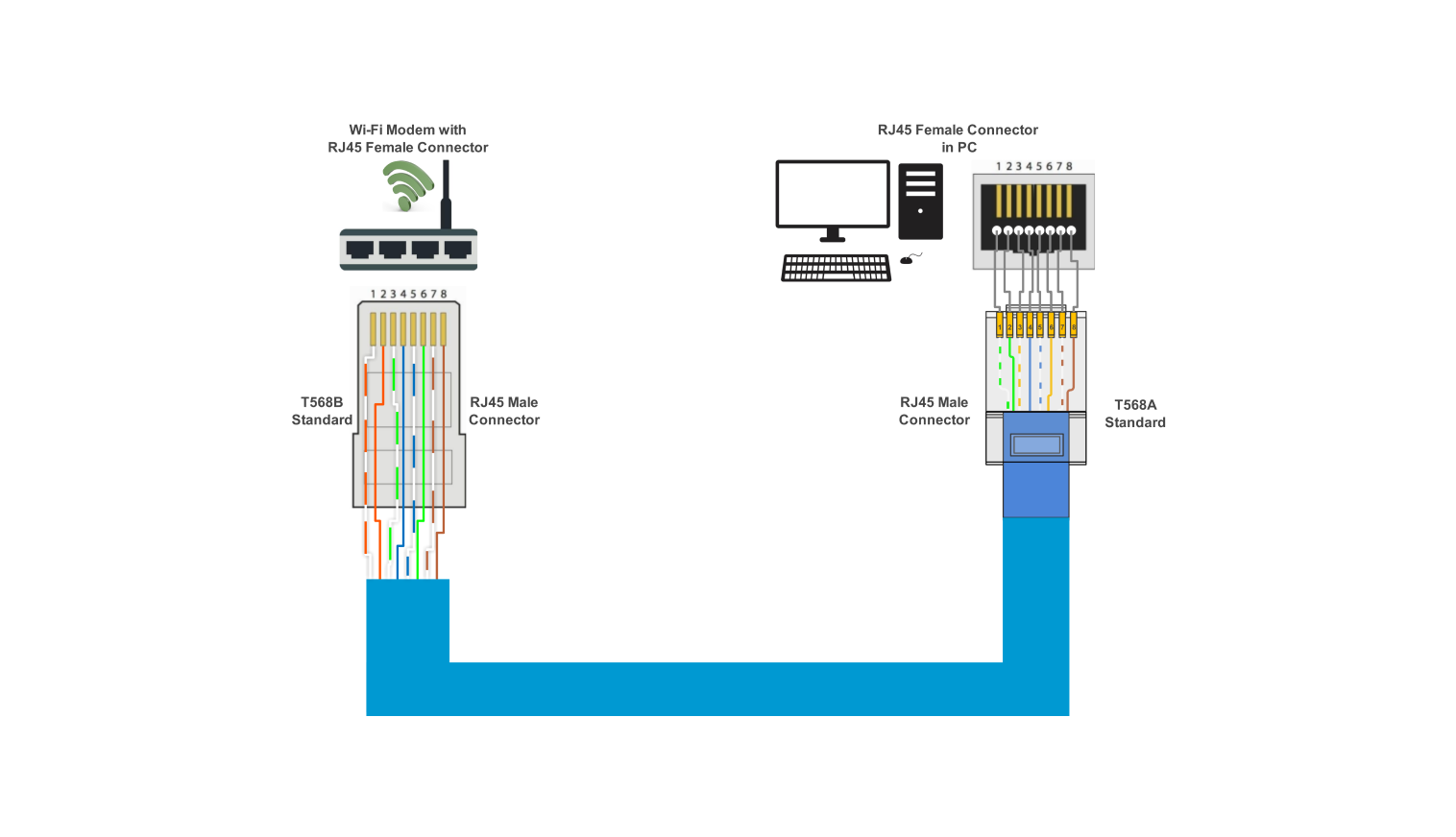

Once the template has opened, look for the Libraries panel on the left side. There you can find all the electrical components that you might want to add in. Drag and drop the needed symbols onto your canvas.

Under Electrical Engineering, expand the Basic Electrical category. You can swap components, adjust values, and even add labels to tailor the circuit. You can also change line styles, colors, and text fonts for better clarity.

Now click File > Export and choose your preferred format (e.g., image file, PDF, SVG) to share and export to the diagram.

Benefit of using Delco Remy alternator wiring diagram

Using a Delco Remy alternator wiring diagram provides significant advantages for anyone involved in maintaining, repairing, or upgrading a vehicle's electrical system.

Firstly, it offers clear guidelines on how the Delco Remy alternator has to be correctly installed and in addition instructions on how it is connected to important components such as battery, voltage regulator as well as instrument cluster.

Secondly, the wiring diagram is again used when handling electrical problems or when undergoing some analysis on certain electrical complications because by revealing the positions of the wires the exact complications performing in a certain job can be recognized.

Their roles include ensuring the wiring diagram necessary to connect the terminals appropriately and meet the manufacturer's requirements is complete. This saves one from making a hurried attempt that might lead to a short circuit or a breakdown/damage to some small parts. The technicians and monikers can quickly make use of the layout to show the areas that need modifications, replacement of parts, alteration of electrical accessories, or mere performance of their usual maintenance procedures to increase the life rating of the circuits in cars.

Frequently asked questions

-

How many amps is a Delco Remy alternator?

When it comes to the amperage output of the Delco Remy alternator, various types of devices are available, and the most common range is from 70 amps to over 200 amps.

-

How does alternator wiring work?

It controls the flow of electricity by providing the means to convert mechanical energy in the engine to electrical by use of the electromagnetic induction principle. In an alternator, alternating current (AC) is created through the application of a rotating magnetic field in the stator windings, which is later converted to direct current (DC) by diodes incorporated in the alternator.

This DC is then supplied to the vehicle's electrical network, in this instance, the battery will be charged and different components powered.

-

What is the minimum gauge wire for alternator to battery?

The minimum gauge wire needed for the connector to directly connect the alternator to the battery depends on the number of maximum output currents of the alternator.

When it comes to alternators, the largest typically seen is 100-amp, which should be good enough with a 4-gauge wire. Alternators with an output capacity of more than 150 amperes may need a thicker 2GA wire, or even larger.

Related templates

Get started with EdrawMax today

Create 210 types of diagrams online for free.

Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free