- All templates

- Wiring diagram templates

- John Deere alternator wiring diagram

About this template

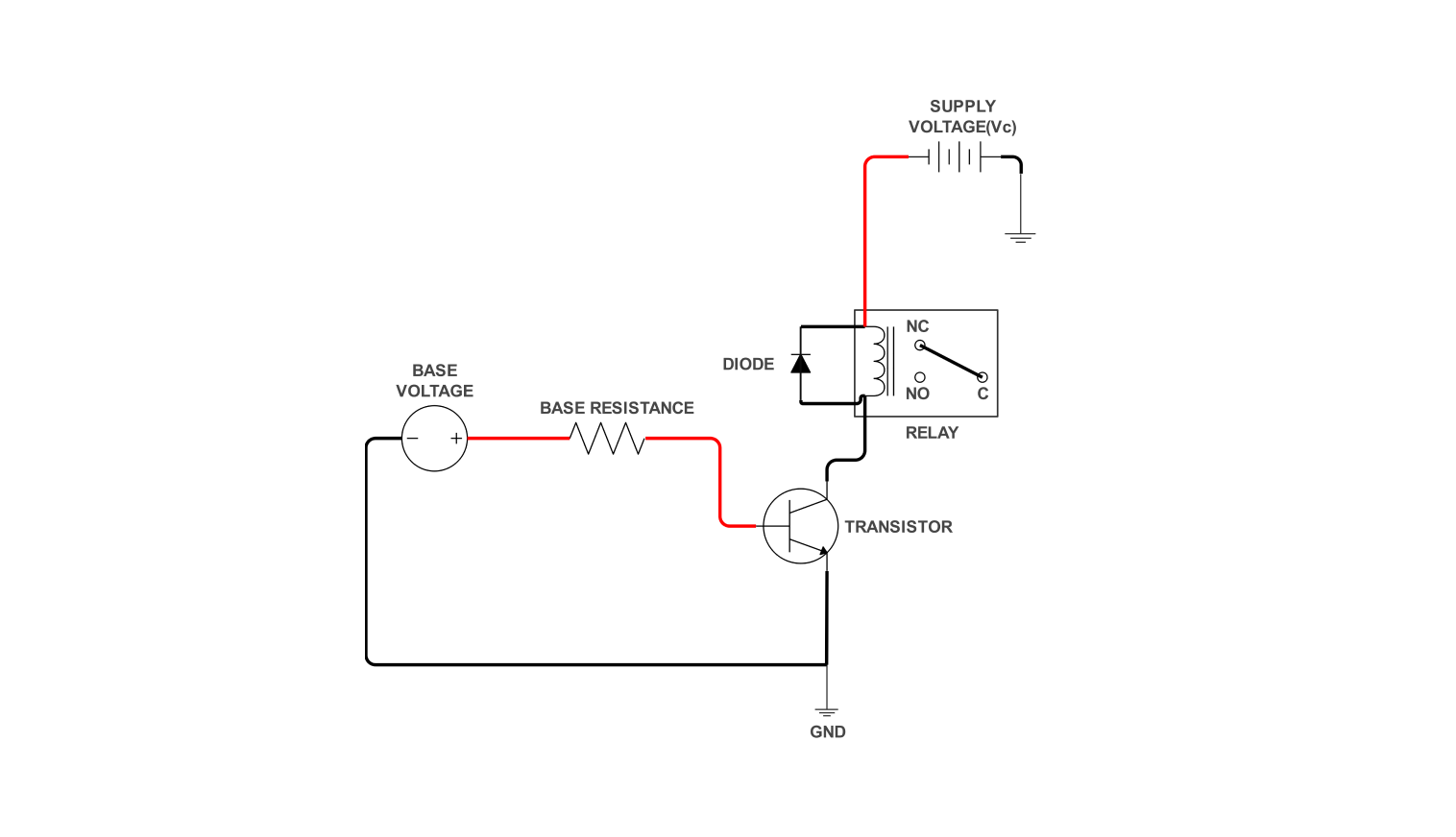

Creating a wiring diagram for a John Deere alternator involves outlining the intricate network of electrical connections among essential components.

Sitting at the core of this figure is the alternator and this is the component that converts the mechanical energy of the engine into electrical energy used in charging the battery and to powering of the electricals in the car.

The instrument cluster can be considered as a type of constitutive control panel or display showing several crucial factors and indications whenever they are necessary for the automobile’s performance.

The starter is used to start the engine; when a key switch is turned on, the starter is engaged through the use of a solenoid; the voltage regulator rectifies the voltage output in the alternator required to charge the battery and supply power for all the circuits.

The junction block can therefore be affirmed to have the roles of distributing electrical power .Also, the harness integrates and links varied segments like the combination switch, side lamps, rear lamps, and fuel gauge sender, as well as the receiver for efficient lighting and management of fuel levels for optimum and enhanced performance of John Deere vehicles.

How to use this template?

Click on Use This Template to open the diagram.

Once the template has opened, look for the Libraries panel on the left side. There you can find all the electrical components that you might want to add in. Drag and drop the needed symbols onto your canvas.

Under Electrical Engineering, expand the Basic Electrical category. You can swap components, adjust values, and even add labels to tailor the circuit. You can also change line styles, colors, and text fonts for better clarity.

Now click File > Export and choose your preferred format (e.g., image file, PDF, SVG) to share and export to the diagram.

Benefits of the alternator wiring diagram

There are several advantages of using an actual wiring diagram of a John Deere alternator system when it comes to the practical application among technicians, mechanics, or operators for such vehicles.

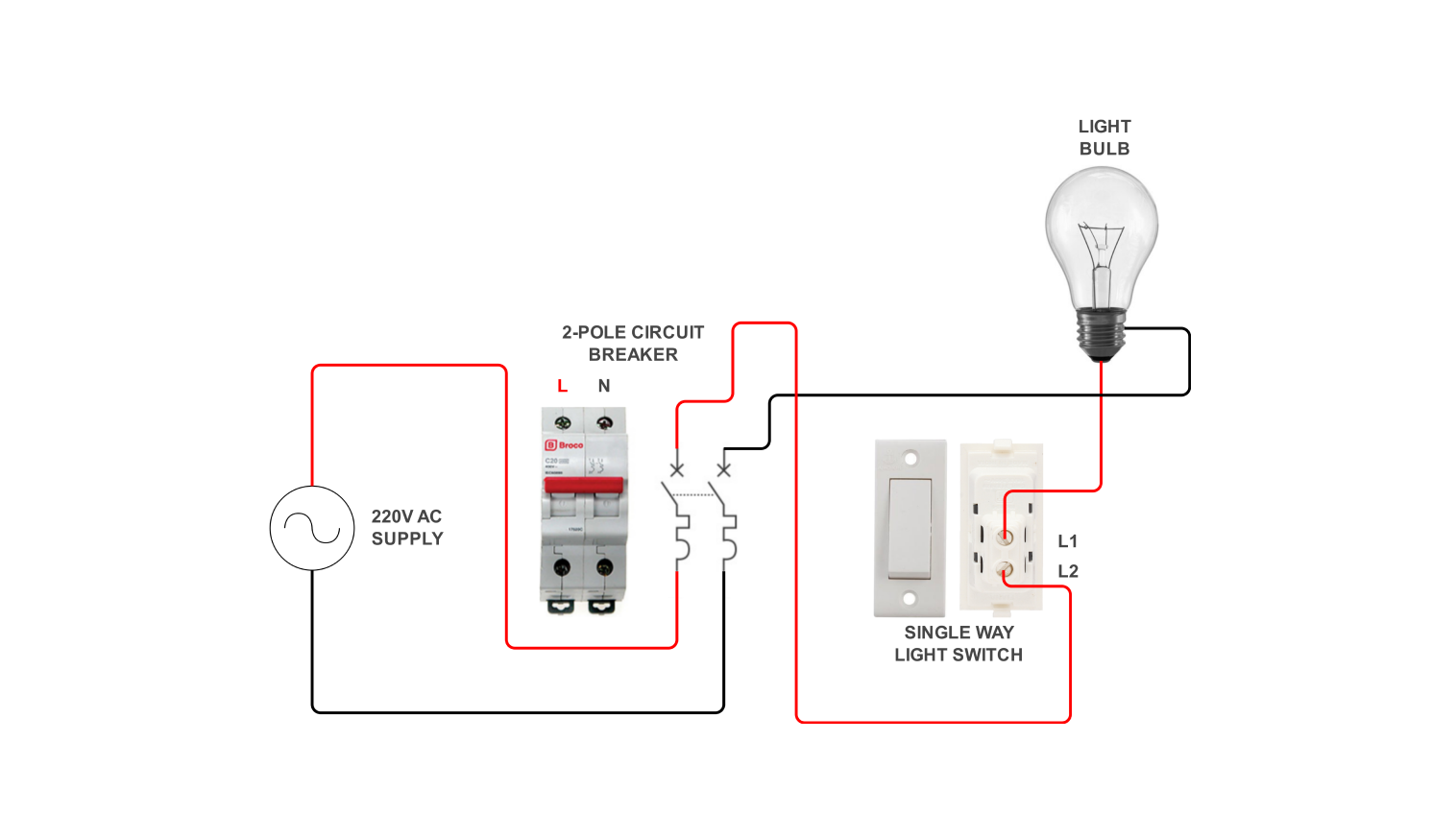

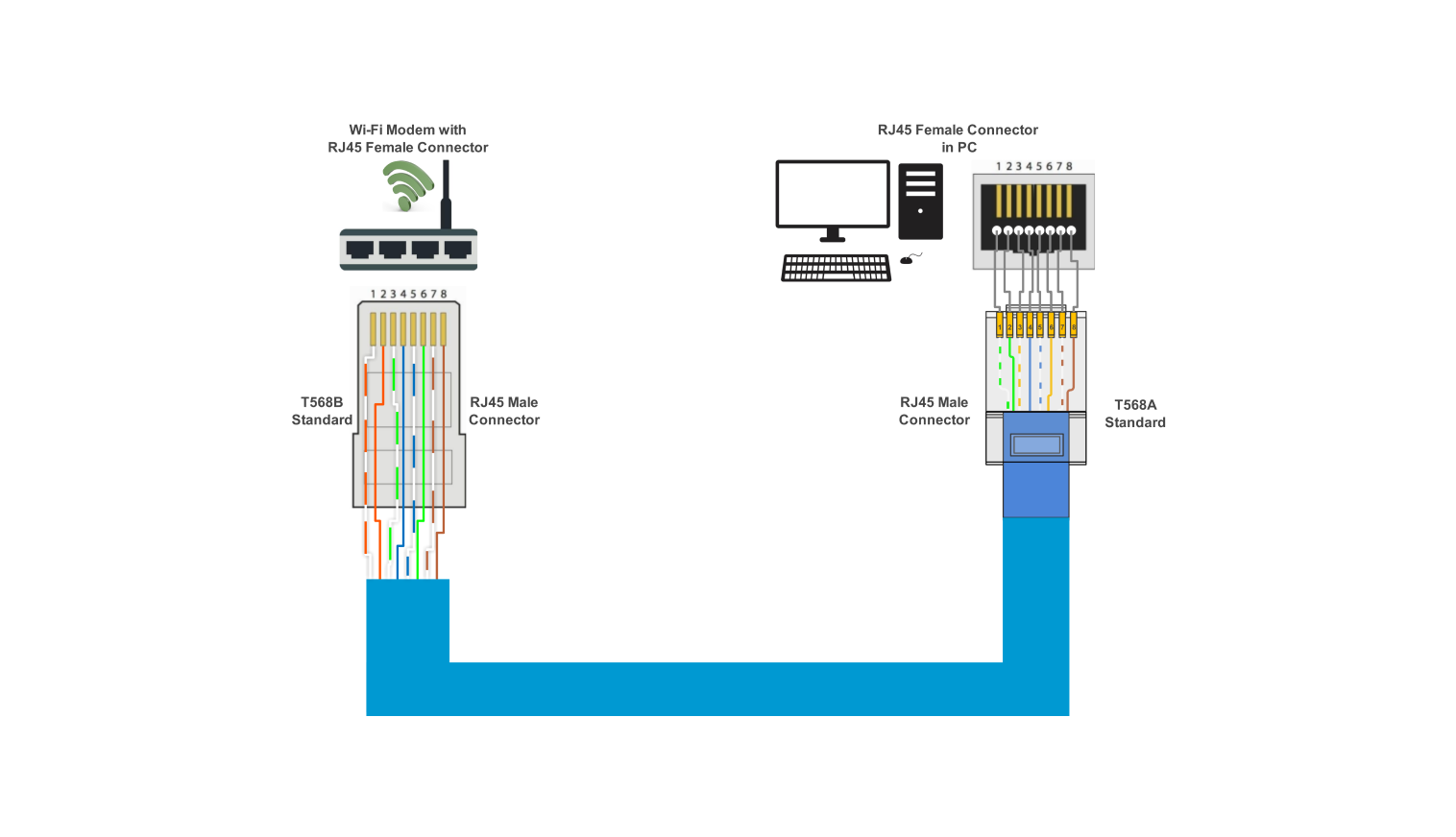

Firstly, it is a visual representation of infrastructure that helps in understanding the number and interaction of inputs and outputs from key features. Any potential complications arising from this multitasking are easily distinguished due to the clear separation of electrical duties, which is useful when solving electrical problems swiftly.

Whether you are diagnosing a charging problem, a lighting problem, or making sure that the fuel gauge is working normally, you can use the wiring diagram to trace the circuit, check connectors, and determine where there are possible problems with high accuracy.

Secondly, due to the electrical wiring diagram, it is easier to comprehend all the relations between the various elements of the electrical system. This can explain the functions of all critical aspects like the alternator, instrument cluster, starter, voltage regulator, and junction block among others.

Such knowledge is crucial when it comes to installations, repairs, or even implementing modifications since it is vital for electrical layouts to match those of John Deere. They are effective in avoiding mistakes that may cause an electrical malfunction or harm the part and so increase reliability and safety.

Frequently asked questions

-

How many wires does an alternator need?

An alternator in a vehicle's electrical system typically requires three essential wires for operation. The battery wire a supply wire that charges the battery and provides power to electrical devices; the Output voltage wire used to control the output voltage for charging the battery; and the ignition switch wire used to connect the alternator to the battery for generating electricity during an engine start.

-

What voltage is alternator wiring?

The voltage output in the wiring of the alternators to the automobiles is commonly between 13.5V to 14.5V when it’s running and zero volts when the engine is off.

-

Is alternator AC or DC current?

An alternator has a rotating magnetic field, which inherently gives AC; its output is DC, as the alternator employs diodes. These diodes rectify the AC before it gets to the battery and electrical components to DC. This DC is crucial to make the automotive system work dependably and maintain continuous and stable voltages to accentuate vehicle performance irrespective of the drive cycles.

Related templates

Get started with EdrawMax today

Create 210 types of diagrams online for free.

Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free Draw a diagram free