In today's fast-paced business landscape, efficient management of inventory can make or break a company's success. To gain a competitive edge, it's essential to have a clear understanding of how data flows within your Inventory Management System. Data Flow Diagrams (DFDs) step in at this juncture.

In this comprehensive guide, we'll take you on a journey to create a DFD for inventory management system with ease. Whether you're a seasoned pro or just starting, our step-by-step approach will empower you to optimize your inventory management and drive your business forward.

Contents of the article

Part 1. DFD And History of Inventory Management System

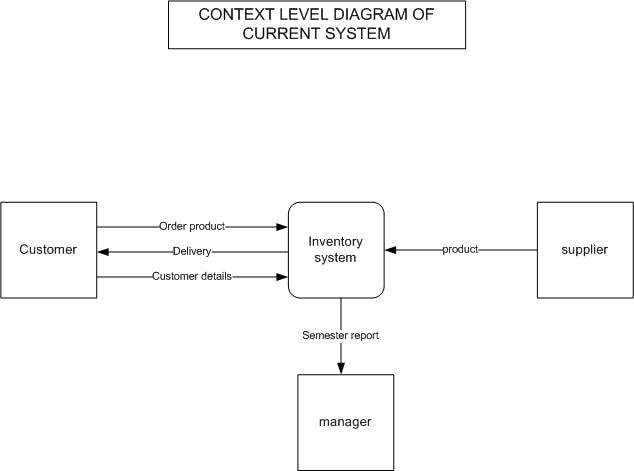

A Data Flow Diagram for Inventory Management System is a visual representation that illustrates the flow of data within the system. It provides a clear overview of how information moves through various processes, entities, and data stores in the inventory management ecosystem. Typically, an Inventory Management System DFD includes elements such as suppliers, inventory databases, order processing, stock monitoring, and reporting modules. Arrows connecting these components signify the direction of data flow, helping stakeholders visualize the system's operations. This DFD serves as a valuable tool for system analysis, design, and optimization, enabling businesses to enhance their inventory management processes for efficiency and accuracy.

The concept of Data Flow Diagrams (DFDs) originated in the 1970s as a key tool in structured analysis and design methods. It was introduced by Larry Constantine, an American software engineer, and Ed Yourdon. DFDs gained traction as a means to represent complex systems in a more understandable and visual format.

Over the years, DFD for inventory management system has evolved and found extensive application in various industries, including inventory management systems. They have become an indispensable tool for analysts and designers to model and optimize data flow within systems, providing a historical foundation for efficient inventory management practices in modern businesses.

Part 2. Types of Inventory Management System

Here are the 5 broad types of inventory management systems:

- Periodic Review System:

- Manual checks and orders at set intervals.

- Simple and cost-effective for businesses with stable demand.

- Just-in-Time (JIT) System:

- Minimizes inventory levels by ordering only when needed.

- Reduces carrying costs but requires precise demand forecasting.

- ABC Analysis:

- Classifies inventory based on importance.

- Focuses resources on high-value items while optimizing lower-priority goods.

- Bulk Shipper System:

- Designed for businesses with infrequent, large orders.

- Efficient for managing inventory with low turnover rates.

- Dropshipping:

- In this specific category, the items are sent directly from the supplier to the customer.

- Eliminates the need for warehousing, reducing inventory costs and storage.

Each type offers distinct advantages, allowing businesses to select the approach that aligns best with their specific operational requirements and market dynamics.

When to use Inventory Management System:

A DFD for Inventory Management System proves invaluable in various scenarios. Firstly, it's crucial for businesses with fluctuating demand, to ensure they maintain optimal stock levels without excess or shortages. Additionally, industries with perishable goods, like food or pharmaceuticals, rely on precise inventory control to minimize wastage. E-commerce businesses benefit from real-time tracking to prevent over-selling and manage multichannel sales effectively.

Moreover, companies with seasonal or promotional fluctuations require an IMS to adapt to demand spikes. Lastly, manufacturing firms use IMS to streamline production by synchronizing raw material availability with production schedules. Overall, a dfd diagram for inventory management system is a vital tool for maintaining operational efficiency and meeting customer demands.

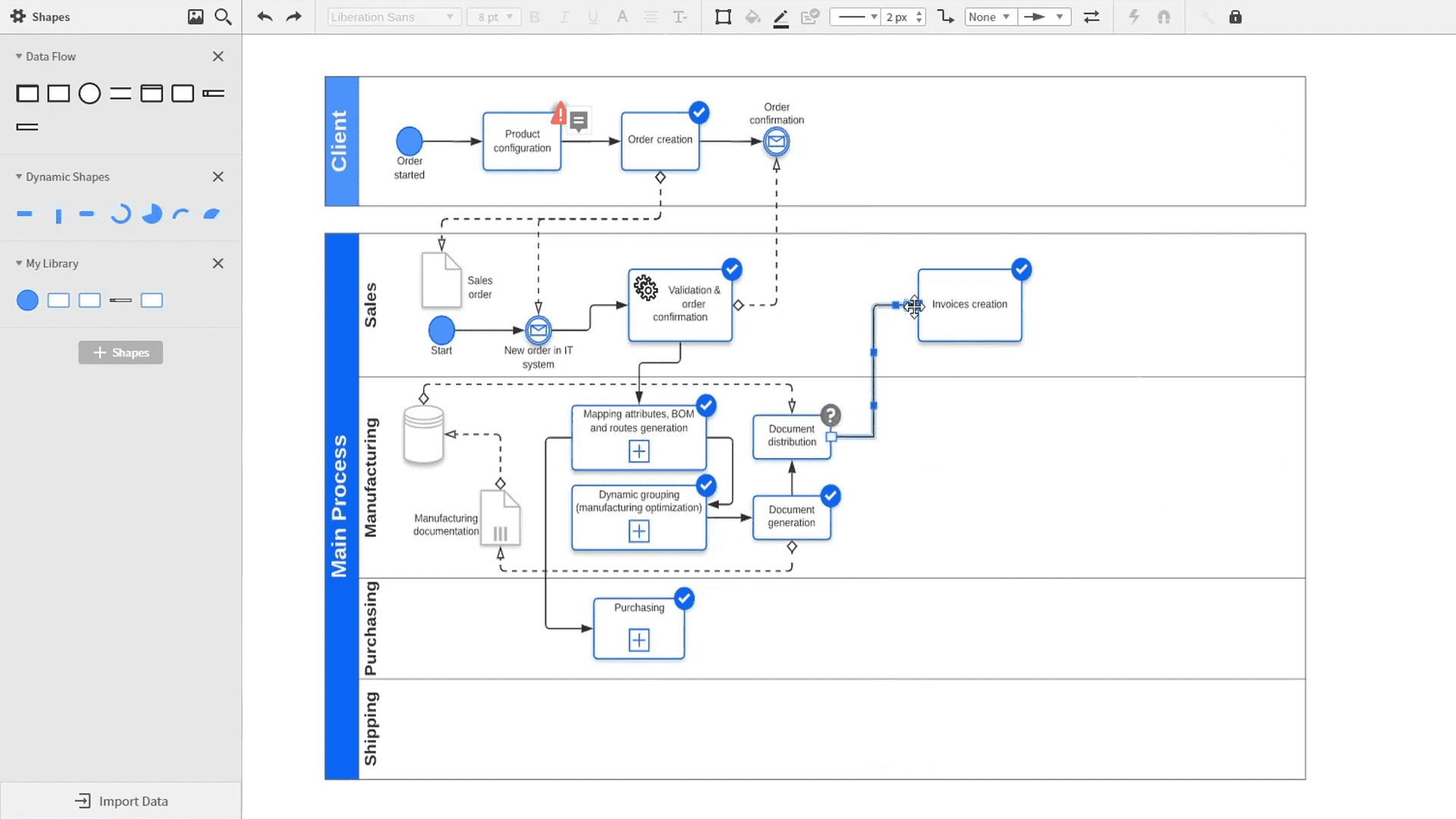

Part 3. Create a DFD Diagram Using EdrawMax

Wondershare EdrawMax offers a paramount advantage in crafting dfd diagram for inventory management system. Its intuitive interface and extensive library of pre-designed symbols and templates streamline the process, significantly reducing the time and effort required.

This user-friendly platform ensures even those with minimal design experience can create comprehensive and visually appealing DFDs. Moreover, EdrawMax's collaborative features facilitate seamless teamwork, allowing multiple stakeholders to contribute and refine the diagram in real time.

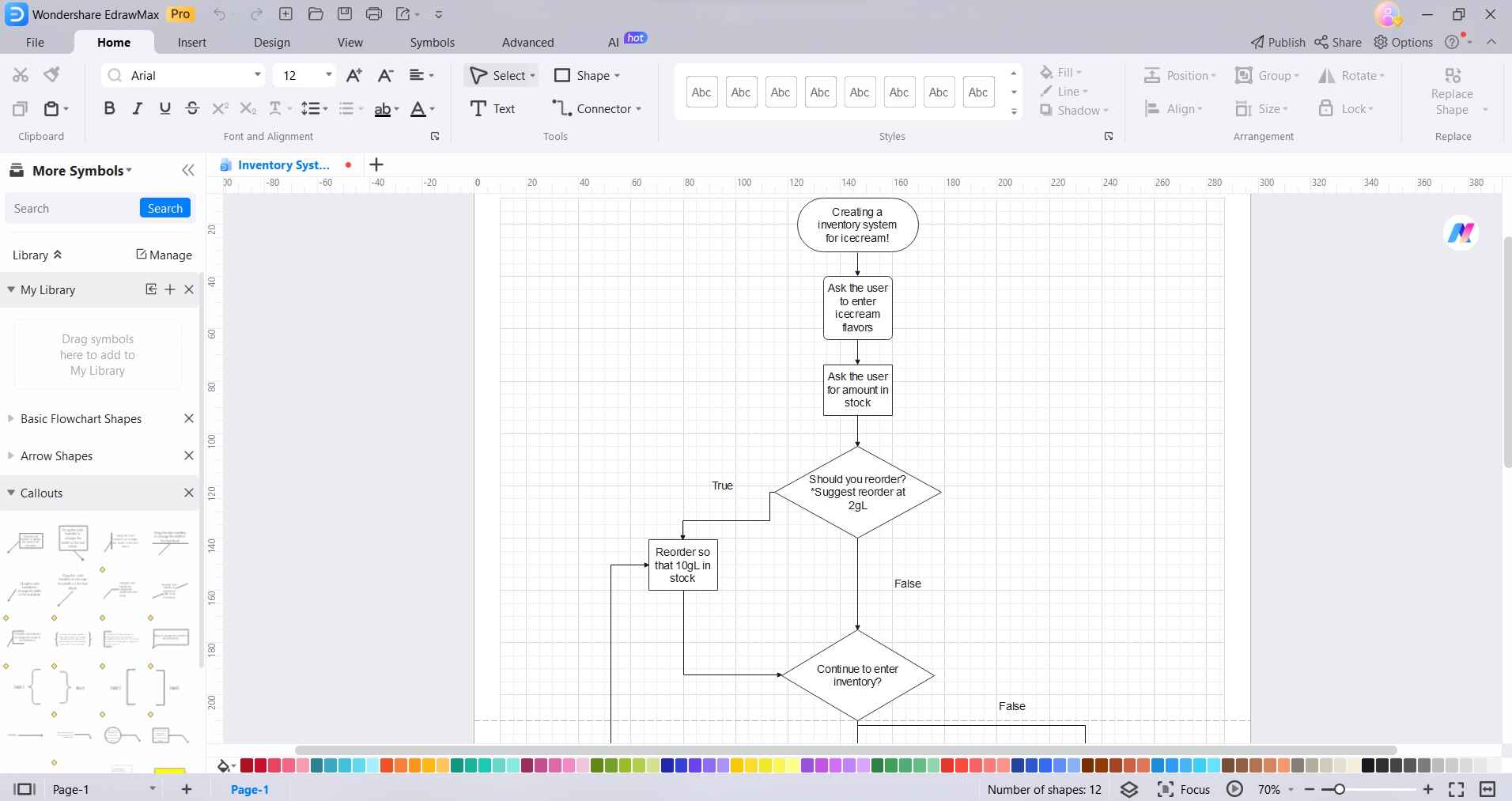

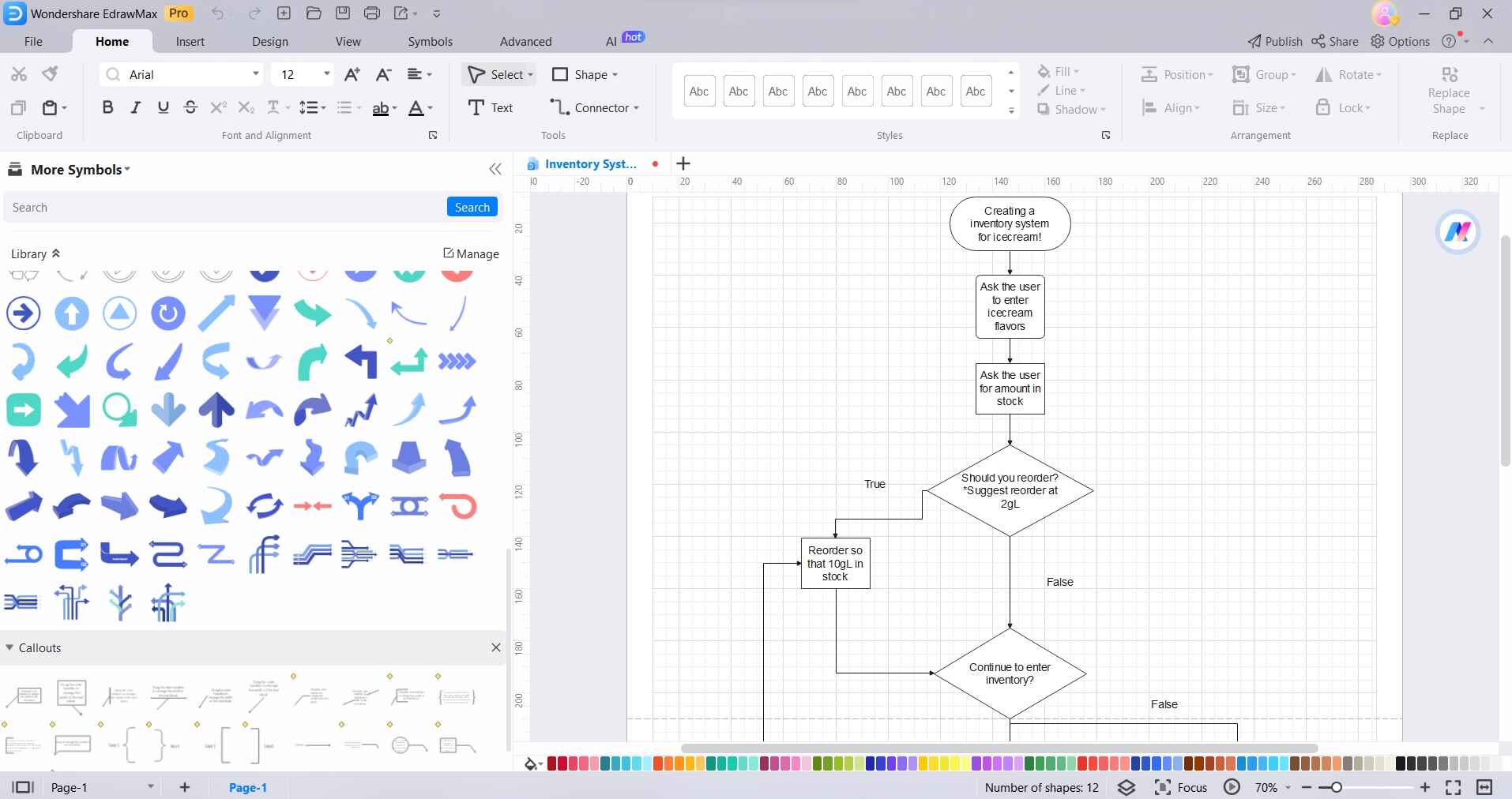

Here are the steps to create a data flow diagram for inventory management system using EdrawMax’s advanced capabilities and features:

Step 1: Open EdrawMax and specifically choose the Inventory Management System DFD template from the available options. This template is designed to streamline the process of creating a DFD tailored to inventory management.

Step 2: Drag and drop symbols for crucial inventory processes such as order processing, stock monitoring, and reporting. Also, include entities like suppliers, customers, and inventory databases on the canvas.

Step 3: Use arrows and connectors to establish connections between the processes and entities, indicating the flow of inventory data. This step illustrates how information moves through the inventory management system.

Step 4: Add descriptive labels to each element to provide clarity on their specific role in the inventory management process. Label processes, entities, and data stores to ensure a comprehensive understanding.

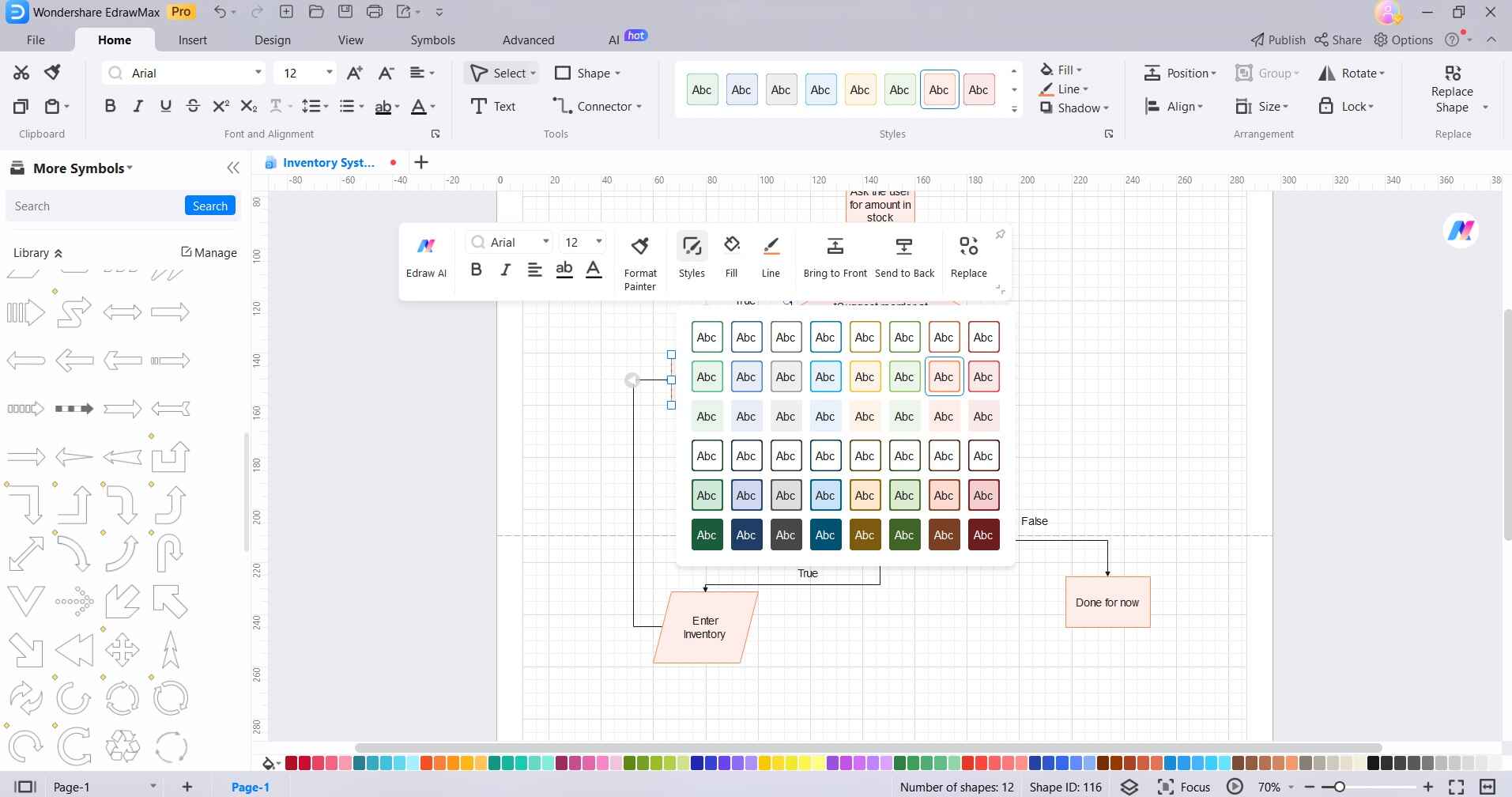

Step 5: Customize the symbols related to inventory processes and entities to make them easily distinguishable. This customization ensures that the DFD is specific to the nuances of inventory management.

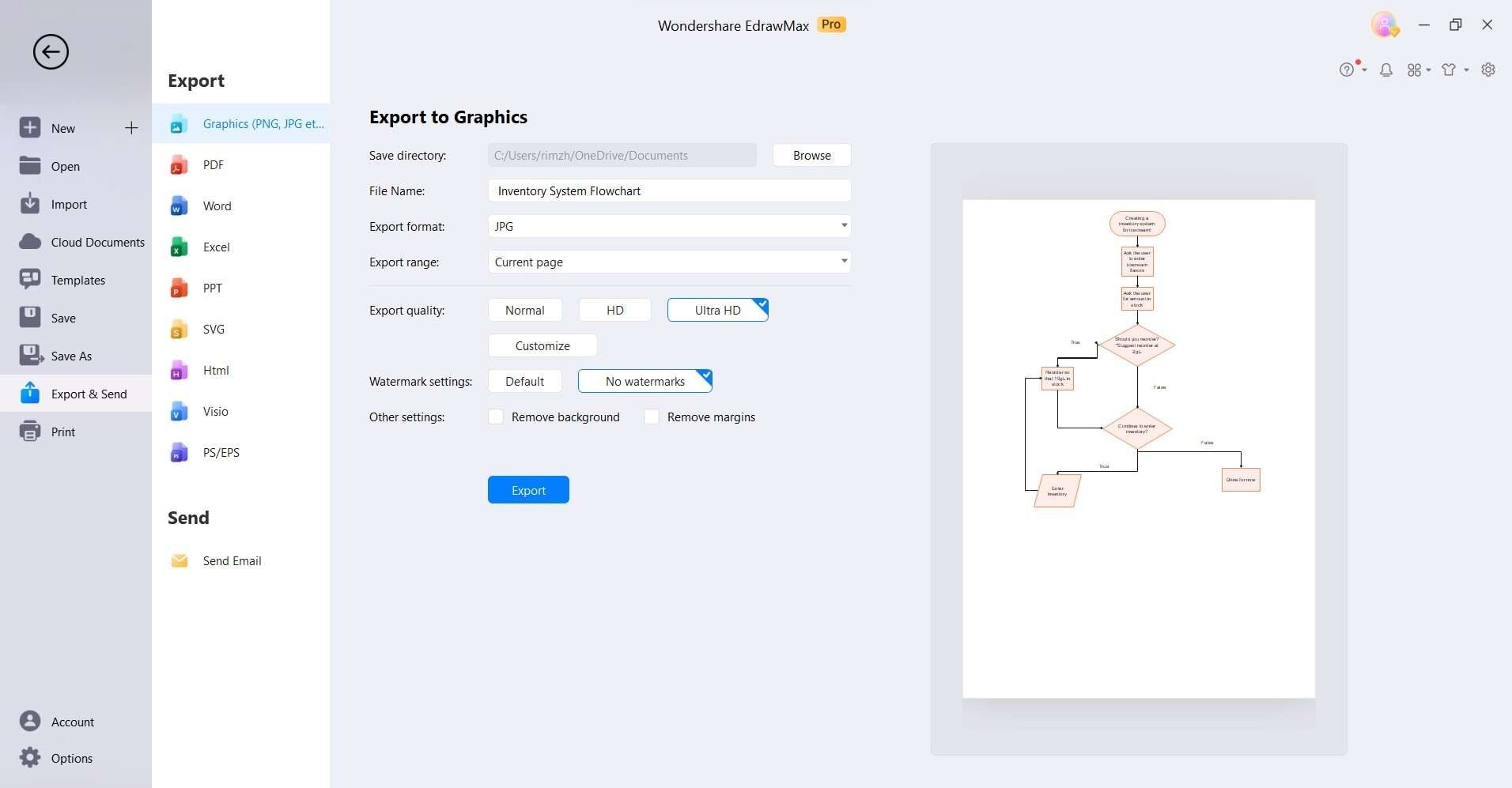

Step 6: Save the project in EdrawMax's format for future reference. Additionally, export the DFD in formats like PDF or PNG to seamlessly integrate it into inventory management reports or presentations.

By following these steps, you can efficiently create a tailored inventory system data flow diagram using Wondershare EdrawMax.

Part 4. Best Data Flow Diagram Maker Recommendations

Here are three outstanding suggestions for data flow diagram maker tools that you can maximize for your needs:

EdrawMax stands out as a top choice for crafting Data Flow Diagrams (DFDs). Its user-friendly interface, extensive library of symbols, and collaborative features make it a go-to tool for visualizing complex systems like Inventory Management.

Lucidchart offers a versatile platform for creating DFDs with its intuitive drag-and-drop interface. It provides real-time collaboration, making it a strong contender for team projects.

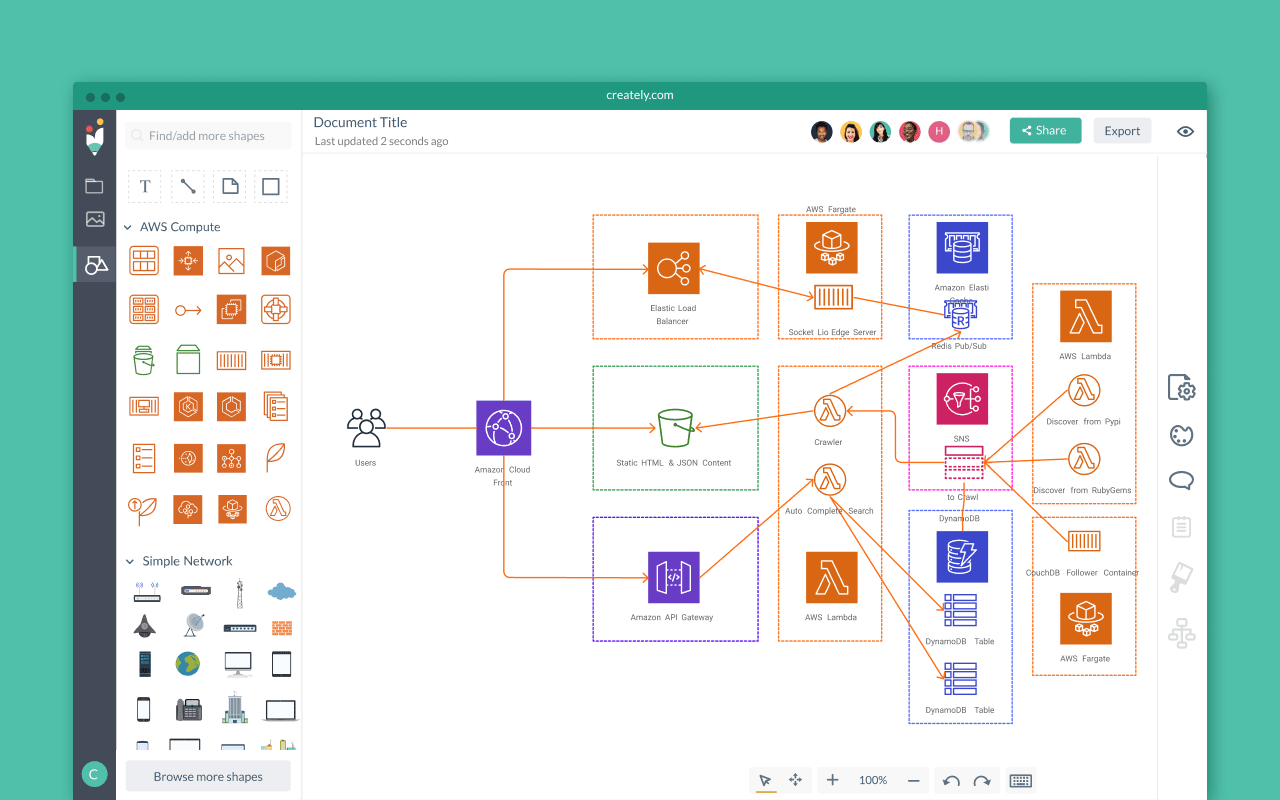

Creately excels in simplifying the DFD creation process. It provides an array of templates and shapes tailored for system diagrams, making it an excellent choice for both beginners and seasoned professionals alike.

Note: Some Techniques of Data Flow Diagram

Data Flow Diagrams (DFDs) employ several techniques to effectively represent system processes and data flow.

- Decomposition involves breaking down complex processes into simpler, more manageable sub-processes. Balancing ensures that inputs and outputs match across levels of decomposition.

- The Gane and Sarson notation method employs circles for processes, rectangles for external entities, and arrows for data flow, providing a clear visual language.

- Lastly, data stores are represented by parallel lines, symbolizing where data is stored within the system.

These techniques collectively facilitate the creation of comprehensive and understandable DFDs for various systems, including Inventory Management.

Conclusion

Mastering the creation of DFD for inventory Management System is an essential skill for optimizing business operations. Through the guidance of tools like Wondershare EdrawMax, the process becomes streamlined and accessible. Understanding the various types of inventory management systems empowers businesses to choose the most suitable approach for their unique needs.

By employing DFD techniques such as decomposition and balancing, a clear visual representation of data flow is achieved. Embracing these practices not only enhances inventory management efficiency but also positions businesses for sustained success in today's dynamic market landscape.