Process flow diagrams (PFDs) are essential in the field of engineering, manufacturing, and process design. They provide a visual representation of the steps involved in a process, allowing for a better understanding of the sequence of operations, equipment, and materials involved. Here, we will delve into the intricacies of process flow diagrams, exploring their definition, purpose, benefits, functionality, research and planning methods, and tips for designing effective PFDs.

In this article

Part 1: What Is a Process Flow Diagram?

A process flow diagram is a schematic representation of a process system, illustrating the equipment, piping, instrumentation, controls, and other elements involved in the process. It uses standardized symbols and notation to depict the flow of materials, information, and interactions within the system. PFDs are crucial in understanding the overall process design and are used by engineers, operators, and other stakeholders to visualize and communicate the process effectively, leading to optimal efficiency.

Part 2: Process Flow Diagrams: Purpose and Benefits

The primary purpose of a process flow diagram is to provide a comprehensive overview of a process system, including its components, interconnections, and operational sequence. By presenting a visual depiction of the process, PFDs facilitate communication, analysis, and optimization of the system.

The benefits of using process flow diagrams include improved clarity and clear understanding of the process, enhanced communication among stakeholders, streamlined process design and optimization, and support for training of employees and procedural documentation.

Part 3: How Does Process Flow Diagram Work?

Process flow diagrams work by visually representing the sequential steps, equipment, and interactions involved in a process system. They utilize standardized symbols and notation to depict various elements such as equipment, valves, instruments, piping, and control loops. The flow of materials, energy, and information is illustrated using arrows and lines, indicating the direction and magnitude of the flow.

Part 4: How to Research and Plan the Process Flow?

Researching and planning the process flow is significant for organizations. To research and plan the process flow efficiently, a systematic approach should be followed.

Define the Scope:

Before creating a process flow diagram, it is essential to define the scope of the process system under consideration. This involves identifying the boundaries of the process, including the inputs, outputs, equipment, and operational parameters to be included in the PFD.

Draw a Draft:

Once the scope is defined, the next step is to draw a draft of the process flow diagram. This involves sketching the major equipment, piping, instrumentation, and control elements based on the available information and initial process design.

Quality Control Group:

In the process of researching and planning the process flow, it is crucial to establish a quality control group to review and validate the accuracy and completeness of the PFD. This group typically comprises experienced engineers, process designers, and relevant stakeholders who can provide valuable insights and expertise.

Part 5: Tips for Designing Process Flow Diagrams

Process flow diagrams should be designed adeptly. Following some essential considerations when designing process flow diagrams is vital.

- Utilize Standardized Symbols:

When designing a process flow diagram, it is important to use standardized PDF symbols and notation as per industry conventions and standards.

- Consider Process Safety:

Incorporate elements of process safety into the PFD, including relief valves, emergency shutdown systems, and other safety-critical components.

- Collaborate with Stakeholders:

Engage with relevant stakeholders such as process engineers, operators, and maintenance personnel during the design process.

- Document Assumptions and Limitations:

Clearly document any assumptions, limitations, or constraints associated with the process flow diagram.

- Review and Revise:

Regularly review and revise the process flow diagram to incorporate design changes, operational enhancements, and new insights.

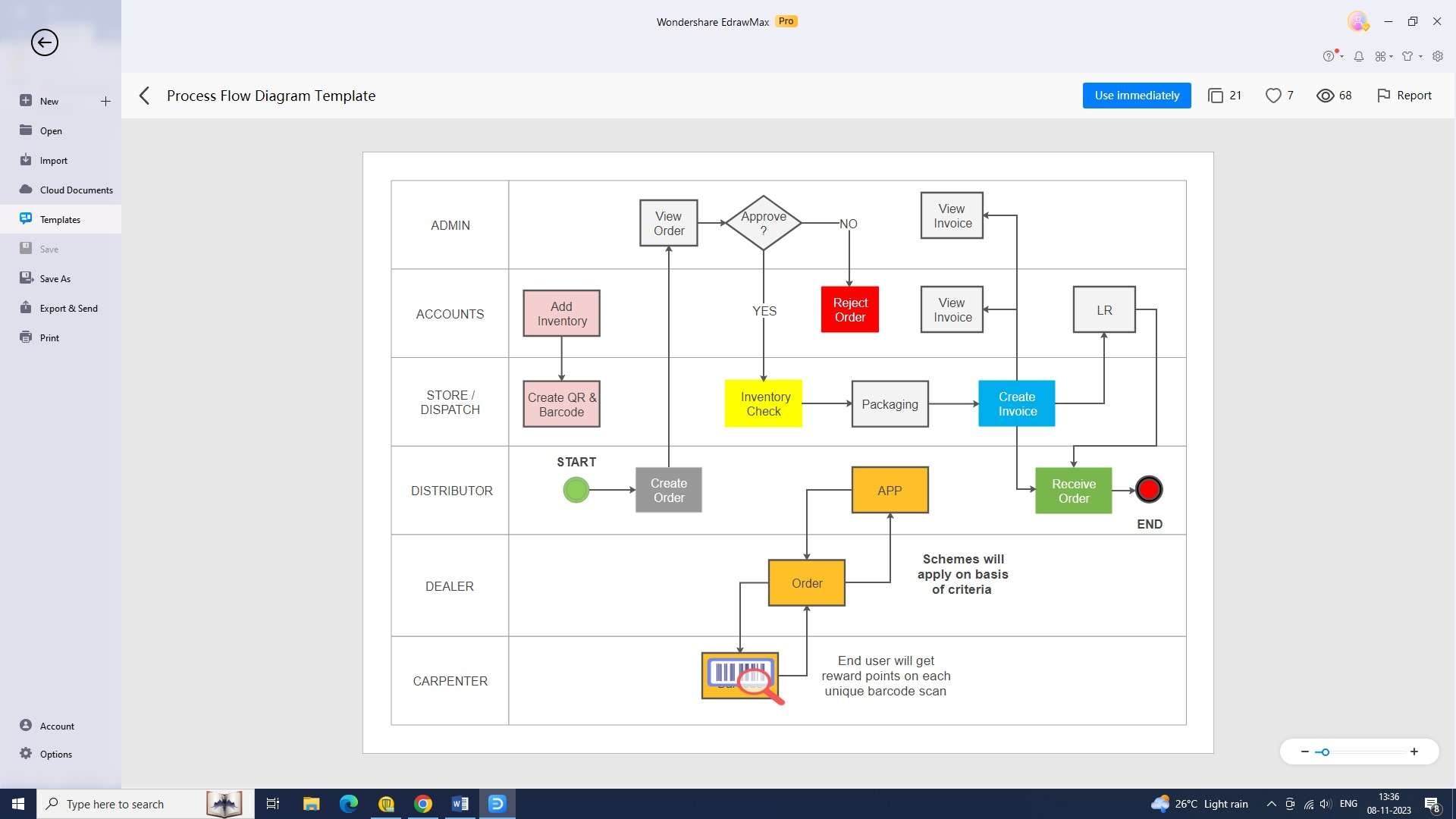

Part 6: Use EdrawMax to Make a Process Flow Diagram

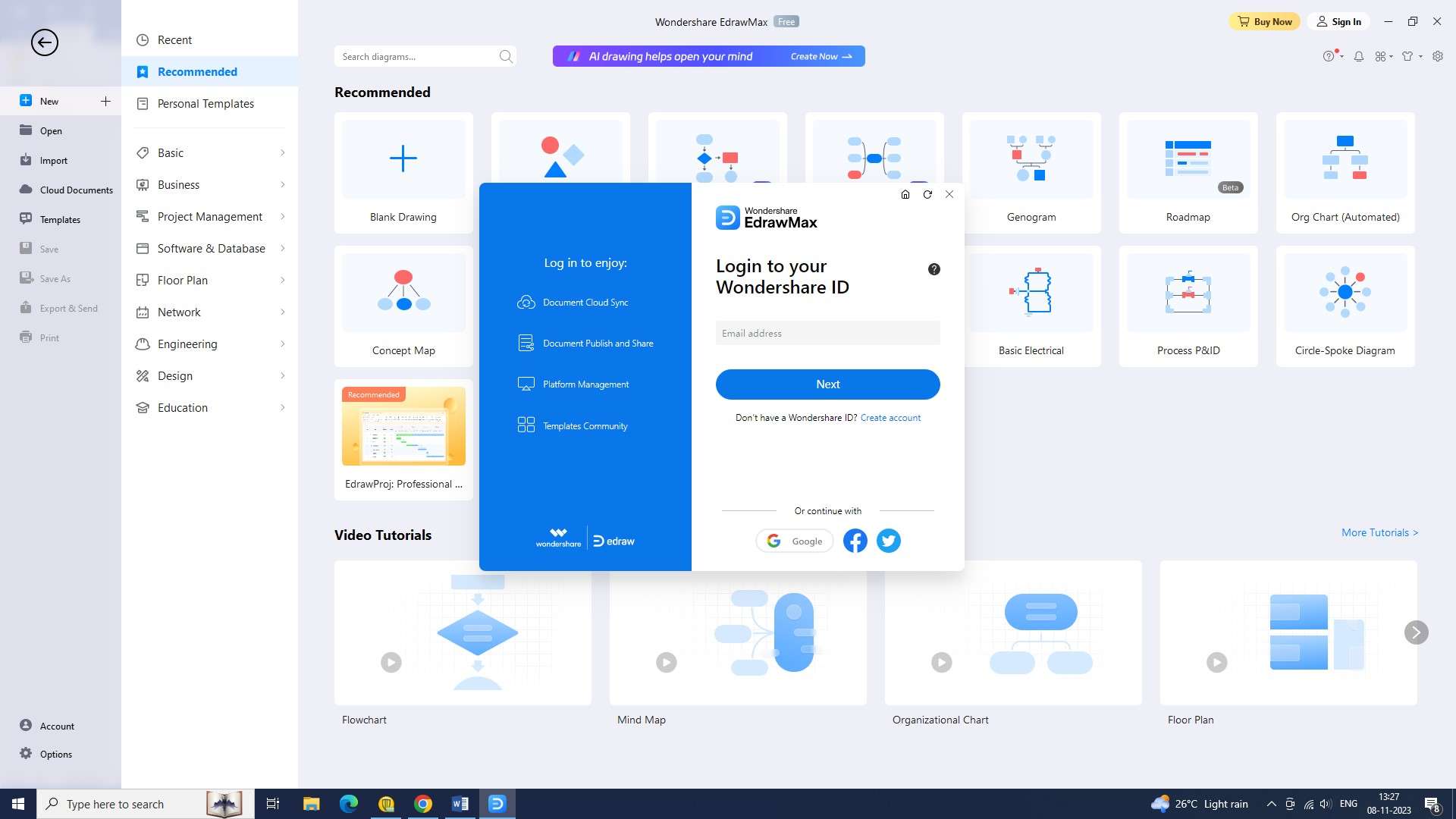

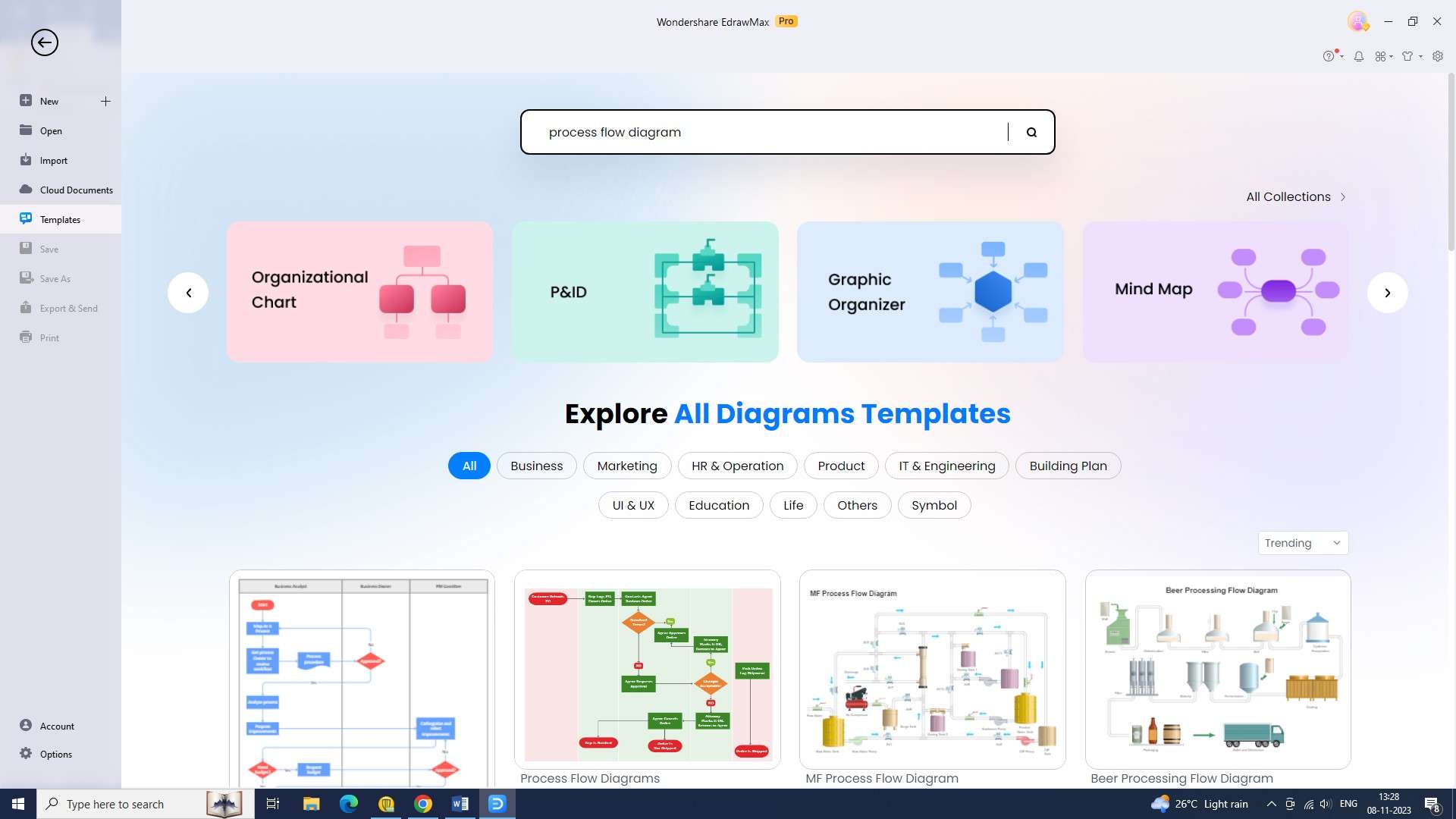

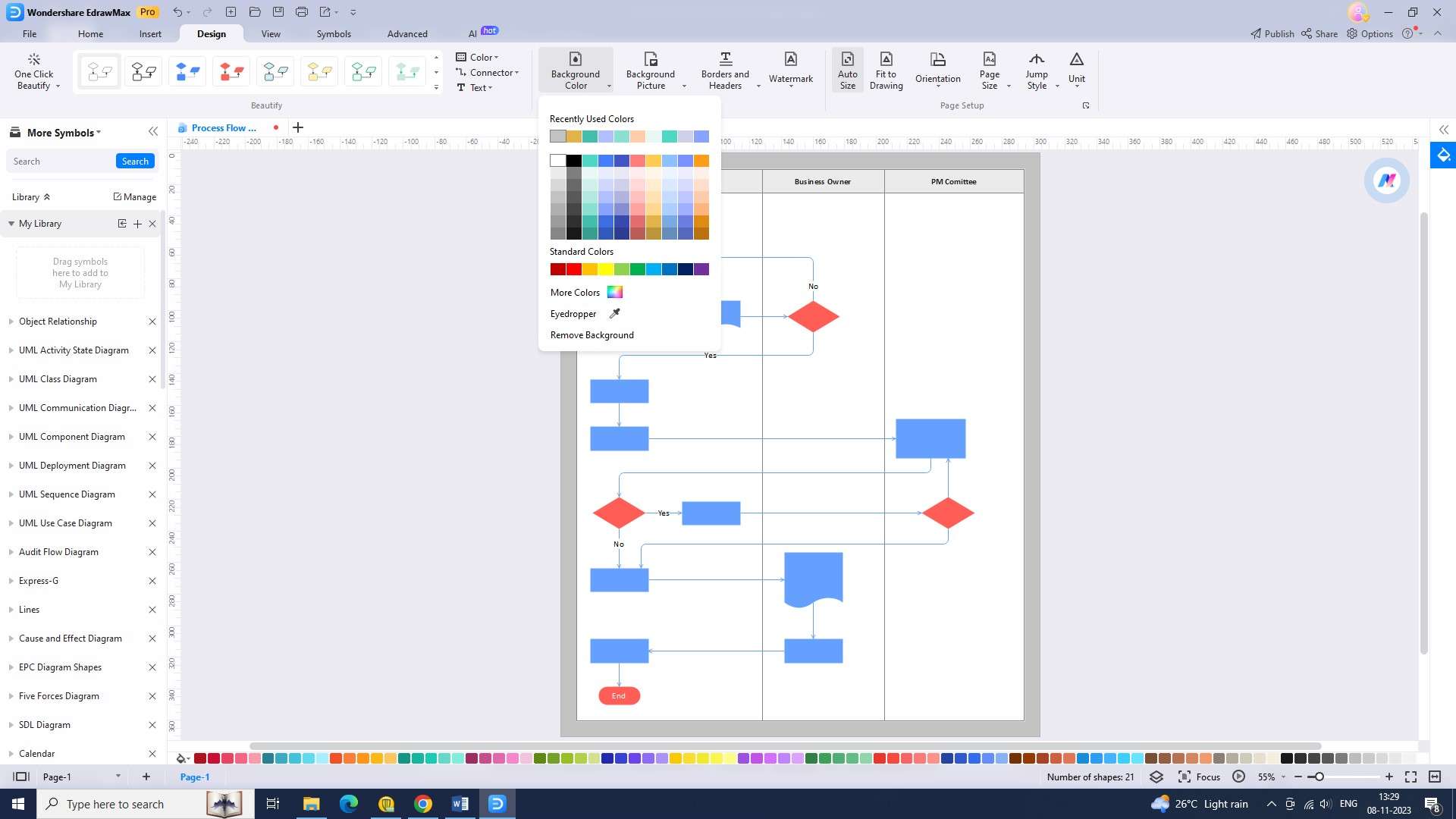

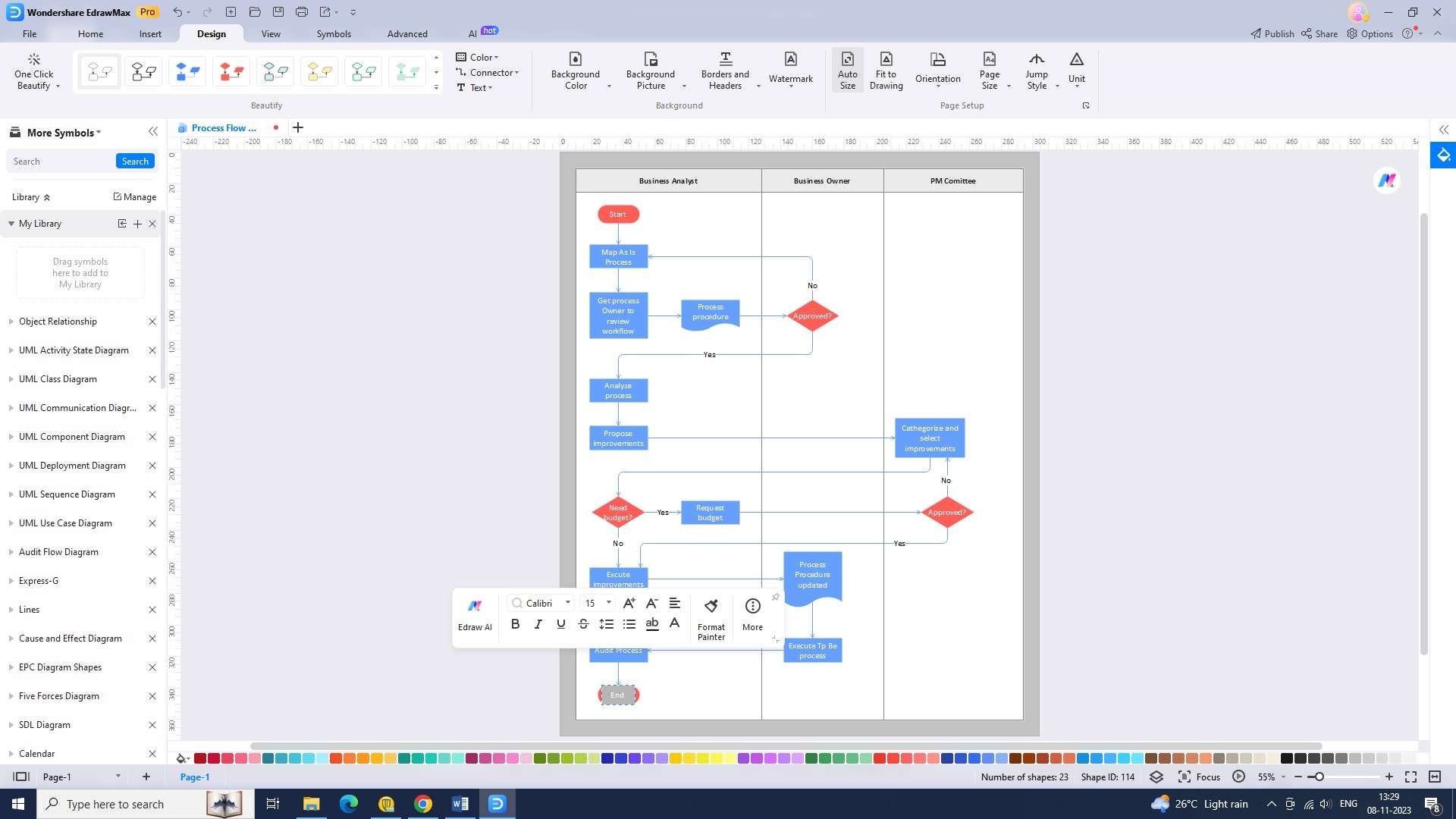

Wondershare Edrawmax offers an easy-to-use drag-and-drop interface that helps you quickly create custom, professional-looking process flow diagrams in minutes. It offers a comprehensive set of symbols and templates to get you started, as well as providing flexible customization and sharing features. These are the steps to create a process flow diagram using the tool:

Step 1

Enter your email address and password to access your Wondershare EdrawMax account and create your process flow diagram.

Step 2

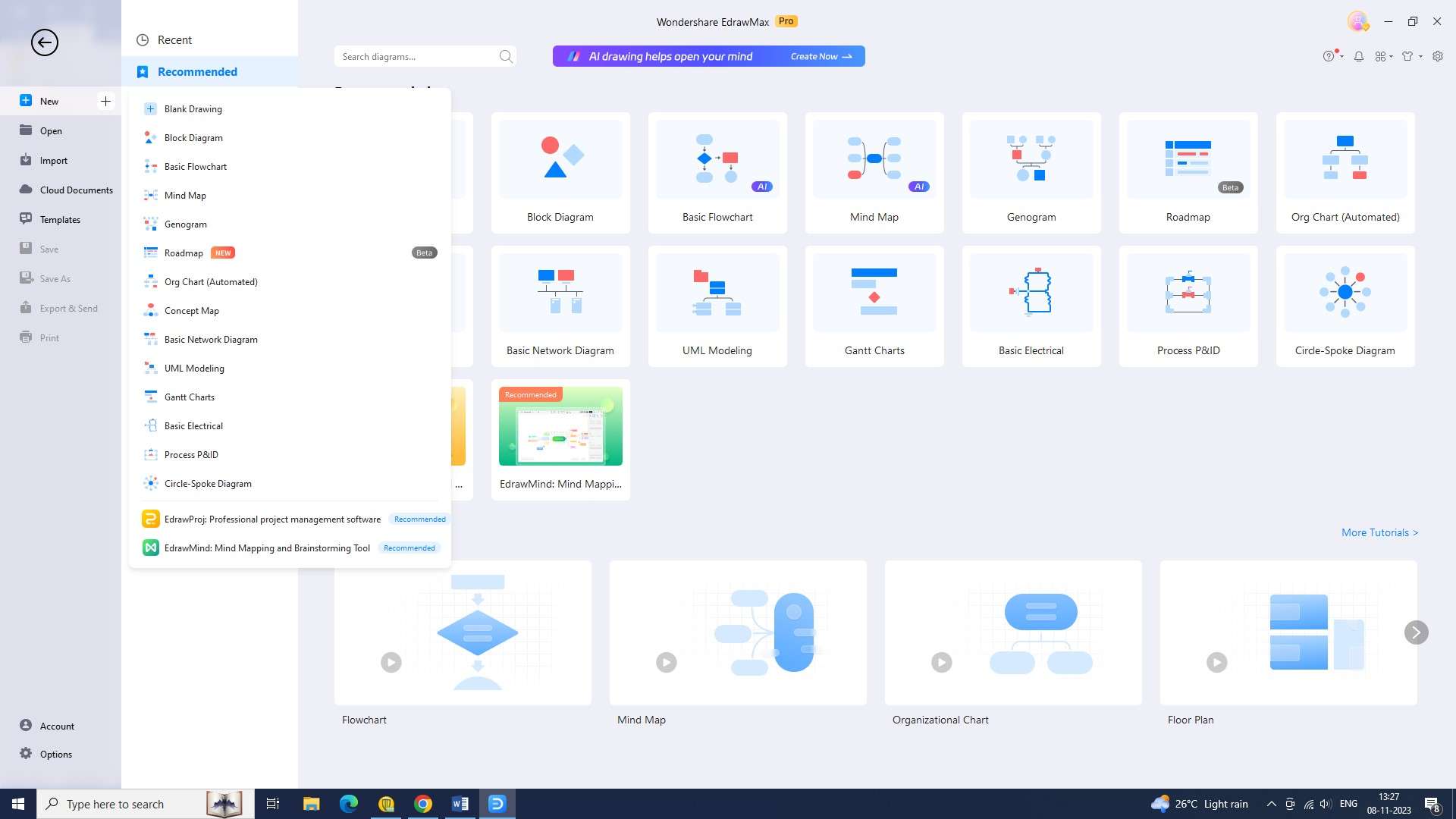

The next thing you need to do after logging into your account is to start a new document. To open a new document, you must click on the + sign that appears next to the "New" button.

Step 3

Selecting the ideal process flow diagram template for your project is the third step. Look through the "Templates" section for a process flow diagram template to accomplish this.

Step 4

Tailoring the template to your project's requirements is the fourth step. You have a ton of choices with EdrawMax for personalizing your design.

Step 5

Now add text to your process flow diagram. It's crucial to describe the meaning of each object in the diagram clearly for better understanding.

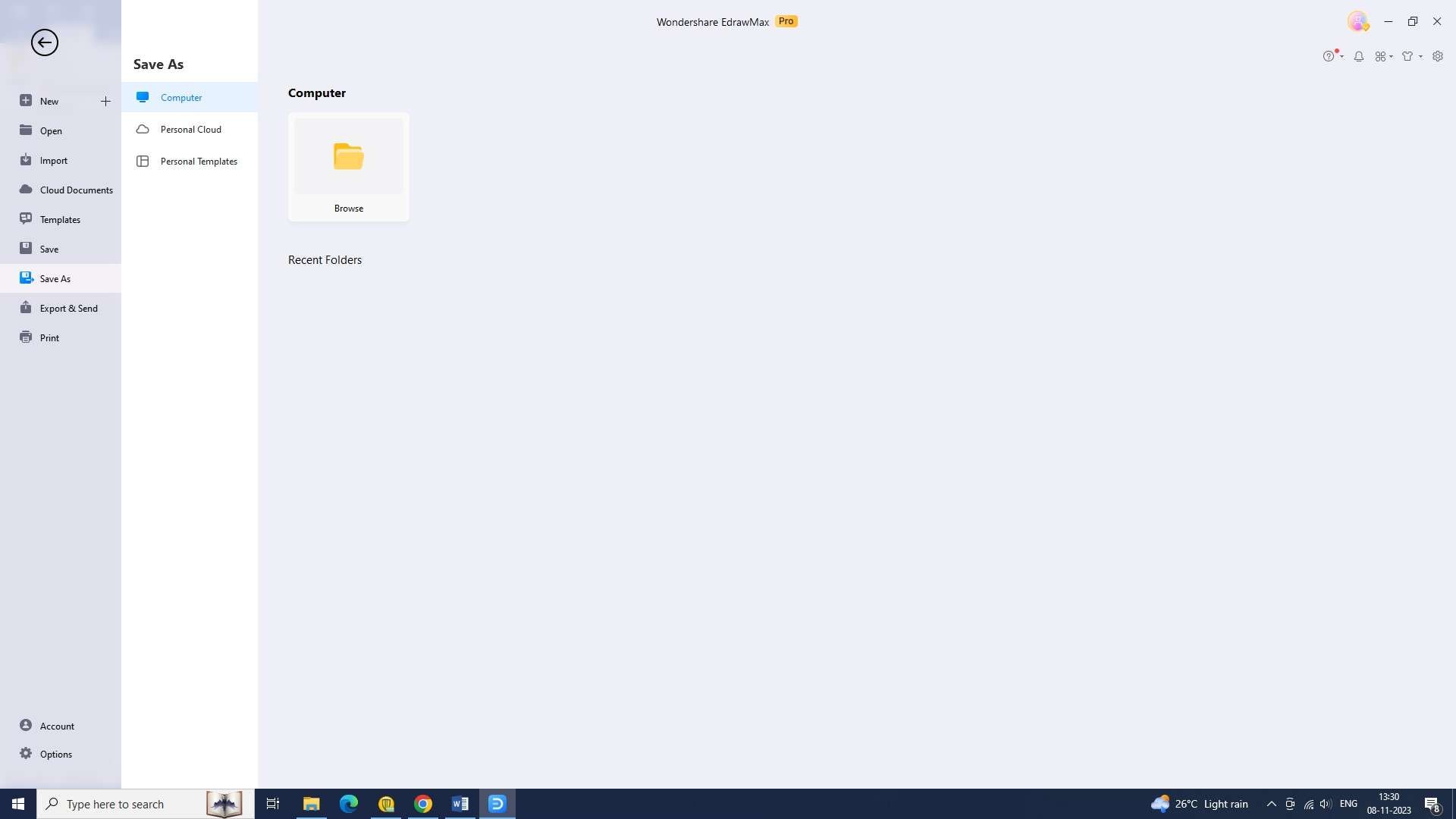

Step 6

Now, you can save your diagram. You will always have the option to make any necessary additions or modifications after saving your diagram.

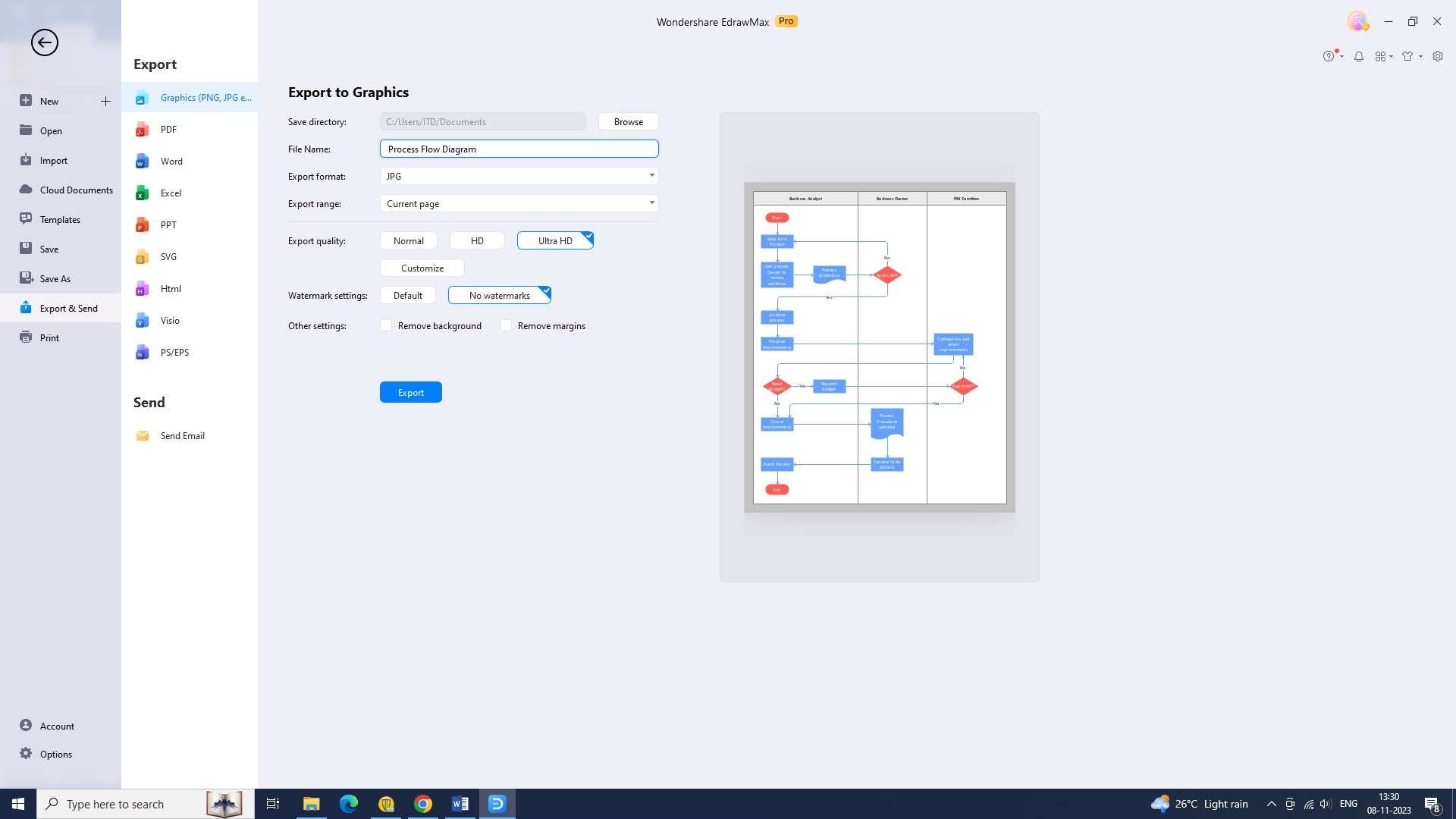

Step 7

Exporting your diagram is the last step. You can export your diagram as a document or share it with others by exporting it.

All in All

Process flow diagrams are indispensable for visualizing, analyzing, and optimizing process systems and are used to standardize a process in order to maximize repeatability and efficiency. By understanding their definition, purpose, functionality, research and planning methods, and design tips, engineers and process designers can effectively utilize PFDs to enhance process understanding, communication, and decision-making.